| Sign In | Join Free | My ecer.com.ru |

|

| Sign In | Join Free | My ecer.com.ru |

|

| Categories | Cycloidal Gear Reducer |

|---|---|

| Brand Name: | FANBAO |

| Certification: | CE |

| Place of Origin: | china |

| MOQ: | 1 |

| Price: | negotiation |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 150sets per month |

| Delivery Time: | 5-8 work days |

| Packaging Details: | standard export wooden case |

| Gearing Arrangement: | Planetary motor |

| Output Torque: | 2.6-1195N.M |

| Input Speed: | 300-1800Rpm |

| Output Speed: | 14-280rpm |

| Weight (KG): | 30kg |

| Ratio: | 9-2800 |

| Material: | Steel or cast iron |

| Port: | Shanghai, Ningbo |

| Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms, Restaurant, Food Shop, Printing Shops, Construction works , Food & Beverage Shops, Advertising Company |

| Company Info. |

| Shanghai Fanbao Industrial Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

BWD3 BLD3 drive reducer single-stage gearbox Speed cycloidal gearbox Reducer

Description :

cycloid gear reducer is a novel transmission mechanism with the principle of Rolling Contact - All major torque transmitting components roll; they do not slide. Rolling motion contributes to minimal friction and high efficiency. Single stage efficiency approaches 93%, and double stage efficiency approaches 86% It is widely used in textile printing and dyeing, light industry food, metallurgical miners, petrochemical, lifting transportation and engineering machinery and other fields.

Feature :

The cycloidal pinwheel reducer produced by our factory is of

excellent quality, reliable performance, complete specifications

and reasonable price.

1.High speed ratio and high efficiency

2.The single stage transmission can achieve the reduction ratio of

1:87 and the efficiency is above%90. If multistage transmission is

adopted, the deceleration ratio will be greater.

3.Compact structure, small volume

Because of the principle of planetary transmission, the input shaft

and the output shaft are on the same axis, so the structure is

compact and the volume is small.

4.Low running noise and low noise

The mechanism of cycloidal needle tooth engagement is large, the

overlap coefficient is large, and the mechanism is stable.

5.Durable and Long Service Life

Because the main parts are bearing steel, after quenching treatment

to obtain high strength, and the part of transmission contact with

rolling friction, so long durable life,The gear tooth profile of

Cycloid Drive enables the sharing of the load by a number of teeth,

thus not susceptible to tooth breakage. At least 66% of ring gear

rollers and cycloidial disc lobes share the shock load under

compression. In addition, major torque transmission Components

inside ,Cycloid Drive are made of high carbon chromium bearing

grade steel hardened to Rockwell Hardness of HRC 61~63 and with

precision grinding. The end result is that Varitron Cycloid Drive

are capable of withstanding intermittent shock load up to 500% of

its catalog torque rating.

6.Reasonable design, convenient maintenance, easy decomposition and

installation, minimum number of parts and simple lubrication, make

cycloidal pinwheel reducer trusted by users.

Specification :

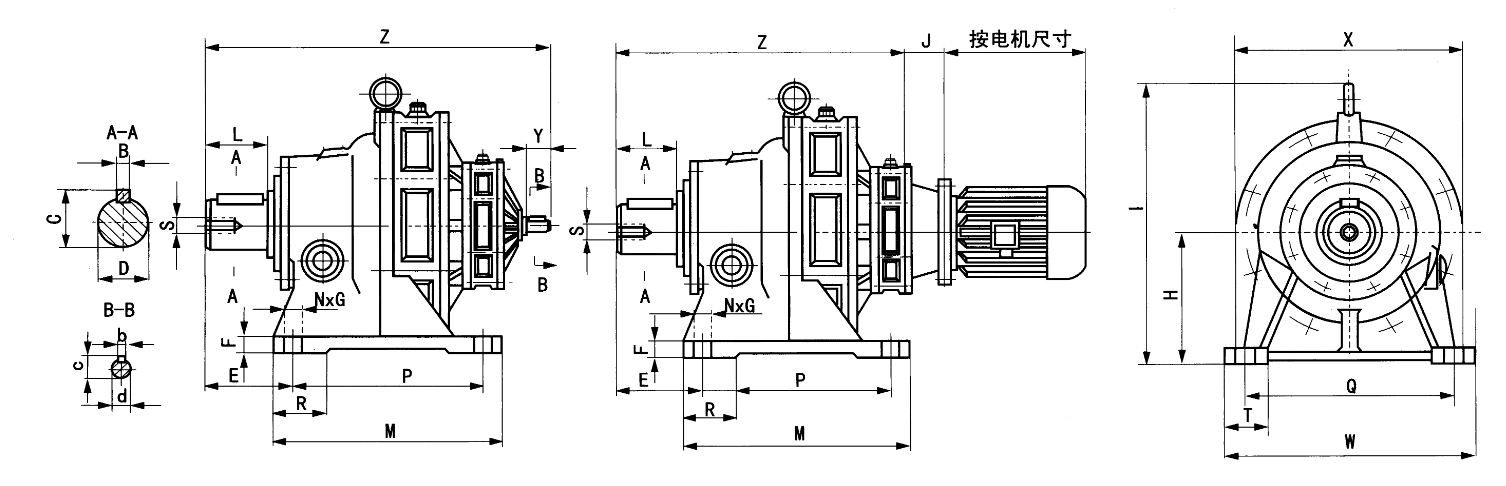

BW,BWD,XW,XWD type(Two stage) shape and installation dimensions

Appearance of a two-stage horizontal cycloid pinwheel planetary reducer

BWE, BWED120-195No.

|