| Sign In | Join Free | My ecer.com.ru |

|

| Sign In | Join Free | My ecer.com.ru |

|

| Company Info. |

| WindSun Science & Technology Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Precision Control and Compact Integration for Industrial Micronization

Jet mills are widely used in the chemical, pharmaceutical, and food industries for ultra-fine pulverization. To meet the demands of precision control and energy efficiency, the FGI FD200 Compact Inverter offers an ideal drive solution. With advanced low-voltage frequency control, it enhances system stability, enables rapid start-stop, and optimizes overall performance in jet mill applications.

Working Principle

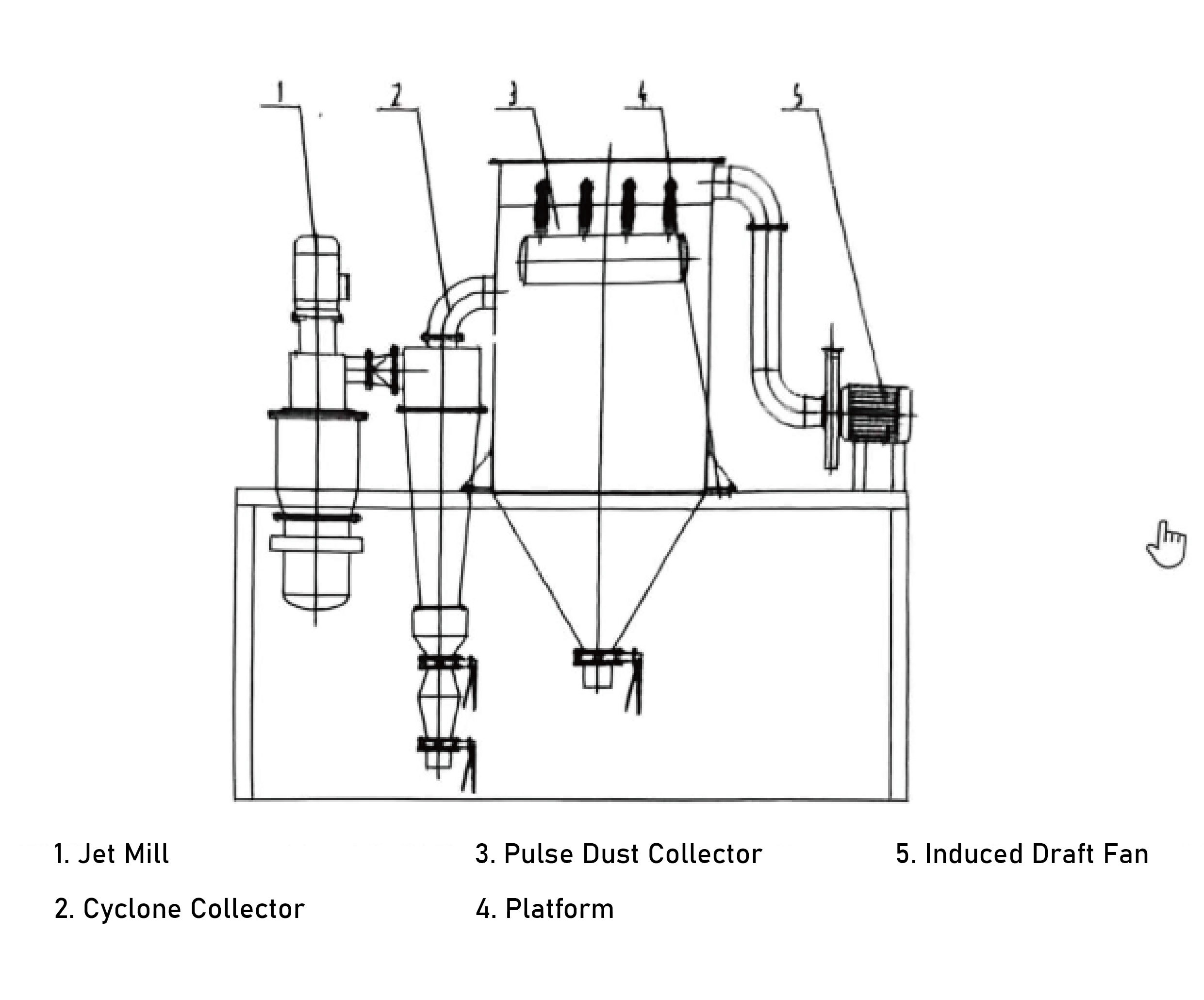

The jet mill system typically comprises a jet mill, cyclone separator, dust collector, and induced draft fan. During operation, compressed air is filtered, dried, and then injected at high speed into the milling chamber through Laval nozzles or similar. At the intersection of multiple high-pressure airflows, particles are repeatedly collided, sheared, and fractured.

The pulverized material is drawn upward by the fan-induced airflow into the classification zone, where a high-speed rotating classifier wheel generates strong centrifugal force to separate coarse and fine particles. Fines that meet the particle size requirement are collected via the cyclone separator and dust collector, while oversized particles fall back into the milling zone for further pulverization.

Laboratory Air Jet Mill Process Flow Diagram

System Advantages

Precision Classification: Optimized airflow design enables particle size control between 1–74 μm (up to sub-micron level).

Wide Applicability: Suitable for materials with Mohs hardness levels from 1 to 10; ideal for de-agglomerating ultrafine powders.

Compact Footprint: Lab-dedicated models occupy less than 2.5㎡.

Equipment Physical Diagram or Equipment Actual Photo

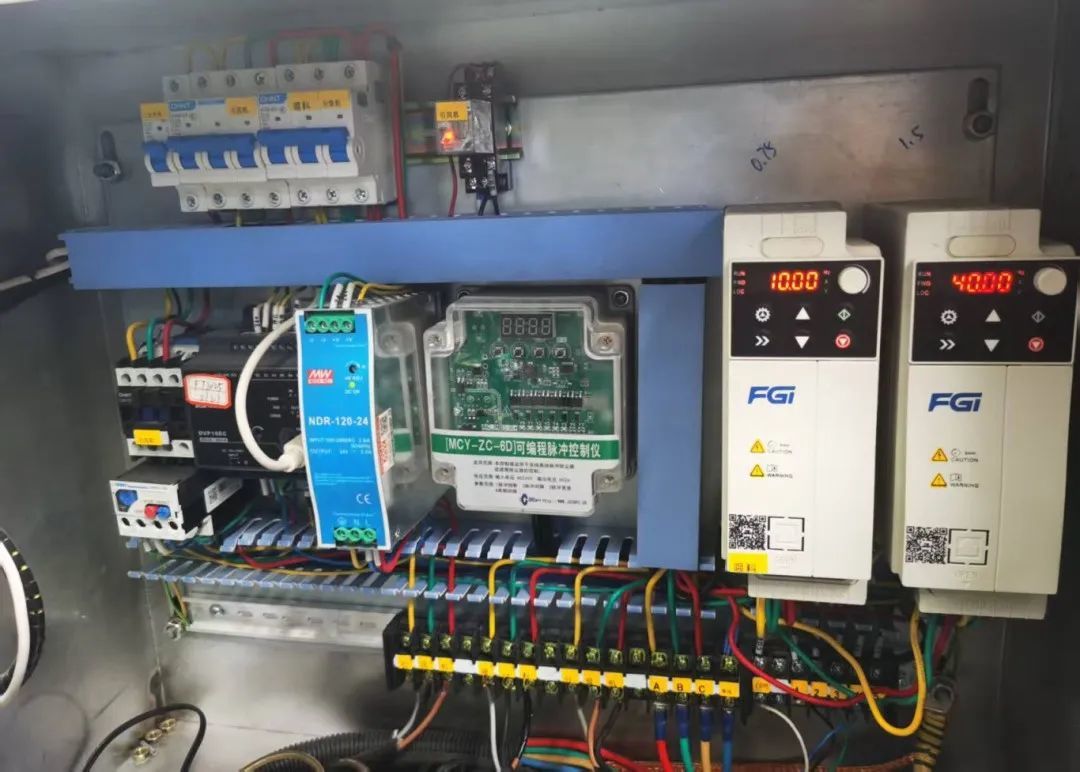

Motor Parameter Configuration

| Equipment | Model | Rated Power | Speed Range | Control Method |

|---|---|---|---|---|

| Classifier Motor | YBM2-90S-2 | 1.5 kW | 0–2876 rpm | Vector control via VFD |

| Feeding Motor | YS-712-4 | 0.37 kW | 0–1400 rpm | Variable frequency speed control |

| Induced Draft Fan | Customized centrifugal fan | 4 kW | 2800 rpm | Direct start at mains frequency |

Control Architecture

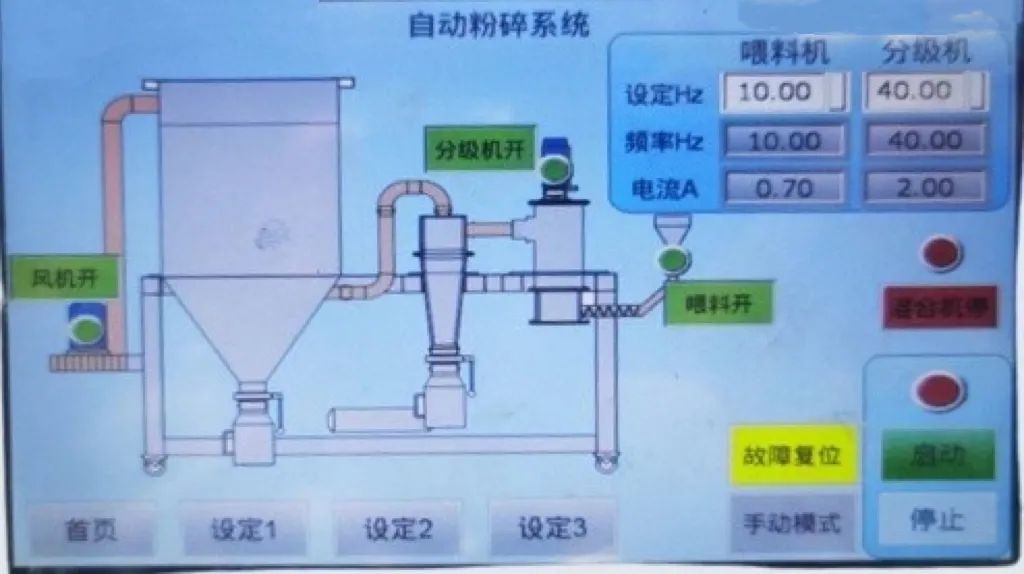

HMI: 7-inch full-color touchscreen (800×480 resolution).

Control Core: PLC communicates with the inverter via MODBUS RTU protocol.

Speed Control: Powered by the FD200 series frequency inverter.

| Indicator | Parameter Specification |

| Control Method | Supports VF control mode, Vector control |

| Speed Adjustment Ratio | Asynchronous motor: 1:200 (SVC), Synchronous motor: 1:20 (SVC) |

| Speed Control Accuracy | ±0.2% |

| Speed Fluctuation | ±0.3% |

| Torque Response | <20ms |

| Torque Control Accuracy | 10% |

| Starting Torque | Asynchronous motor: 0.25Hz/150% <br> Synchronous motor: 2.5Hz/150% |

| Overload Capability | 150% rated current for 1min, 180% rated current for 3s |

Performance Highlights

(Refer to detailed specification sheets for parameter data.)

Core Advantages

Space-Saving Design

Book-style housing reduces volume by 30% compared to similar products

Supports DIN rail, side-wall, wall-mounted, and side-by-side installation

Intelligent Control

Built-in PID algorithm for precise process control

Comprehensive Protection

Overcurrent, overvoltage, and phase-loss protection

Communication Compatibility

Supports MODBUS industrial protocol for seamless system integration

Equipment failure rate significantly reduced, lowering maintenance costs

Installation space reduced by 45%, cutting electrical cabinet costs by approx. 20%

Improved speed control accuracy with vector control vs. traditional V/F methods

Enhanced classifier motor precision, increasing product yield and quality

The successful application of the FGI FD200 Compact Inverter in jet milling systems demonstrates its ability to:

Solve fine particle size control challenges through high-precision vector control;

Meet space-constrained application scenarios, particularly in laboratory or pilot-scale production environments.

FGI continues to provide efficient, reliable, and compact drive solutions to support the performance upgrade of advanced industrial systems.

Production Base: Jincheng Road, Economic Development Zone, Wenshang County, Jining City, Shandong Province, China

Email: overseas@fengguang.com

|