| Categories | Stone Paper Sheets |

|---|---|

| Brand Name: | STONE PAPER |

| Model Number: | RBD |

| Certification: | FDA REACH ROHS |

| Place of Origin: | CHINA |

| MOQ: | 1000KG |

| Price: | USD1200-1600/TON |

| Payment Terms: | T/T |

| Supply Ability: | 10000TONS PER YEAR |

| Delivery Time: | 20 DAYS |

| Packaging Details: | SHEETS, ROLLS |

| Color: | White |

| Size: | Customized |

| Material: | CaCO3, HDPE |

| Feature: | No taxico No pollution Biodegradable |

| Packaging: | Sheets |

| Loading port: | Tianjin |

| Company Info. |

| Shenzhen Shizhineng New Paper and Plastic Application Research and Development Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Recycled Board Paper Double Coated Stone Paper RBD300 Eco Friendly Waterproof Tearresistant For Cover Page Origami

Stone Paper is about sustainable development with respect to our planet. By using mineral power (Calcium Carbonate) Stone Paper bags and packages are tree-free, and no water or bleach is used during production, which is the case during the production of traditional wood pulp paper. Stone Paper is ISO 14001:2004 certified, alongside ROHS, REACH and FDA. Above all, Stone Paper has the C2C silver certificate.

Stone paper, also known as rich mineral paper, achieves all these things: stone paper uses no tree fibre, saving 20 trees per tonne of paper produced. It uses no water, saving 7,480 gallons of fresh water per tonne of paper produced, reduces or eliminates chemical waste, and reduces solid and air waste.

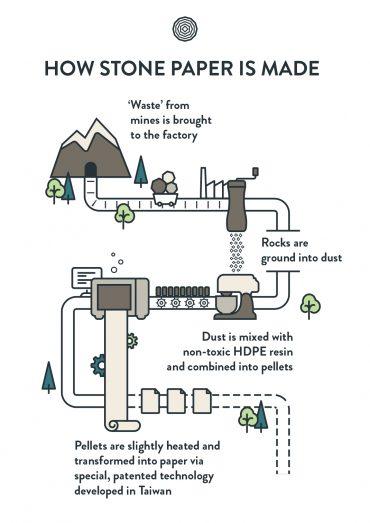

Stone paper is made using calcium carbonate, a compound found in rocks, and bio-resin. The two materials are combined to form a non-toxic and recyclable material that has the texture and look of regular paper. The production process involves crushing the calcium carbonate into powder, melting the resin, combining the two ingredients together and then cooling them. Once cooled, the mixture is extruded through rollers which form sheets of stone paper. The sheets are then cut into desired sizes for use as stationery items such as notebooks or cards.

The Features of (RBD) Rich Mineral Board Double Coated Stone Paper

For plastic/ paper board applications

200-400 mircrons thick

60% calcium carbonate + 40%PE

| Type | Thickness | Density | Base Weight | Opacity | Applications |

| um | g/cm3 | (g/m2) | |||

| (micrometers) | |||||

| (RBD) Rich Mineral Board Double Coated | 250 | 1.5 | 375 | >90% | Paper bags,Kid's books,Calendar, leaflets, brochures, packaging,boxes, gift boxes, Album of paintings,Displays, outdoor applications, |

| 300 | 450 | >90% | |||

| 350 | 525 | >90% | |||

| 400 | 600 | >90% |

1. How is stone paper made?

The stone paper production process is an invention from Taiwan. Over the past 20 years, a technology was developed to produce paper with less impact on the World than traditional pulp paper. The stone paper now has a Cradle to Cradle silver certificate and the technology is spreading rapidly around the World. We would like to share the basic process of making stone paper.

The stones used for the production of stone paper are calcium carbonate, and come from mines. The color of the stones, is the color that the paper will take on. Therefore, mainly white/yellow-white stones are used.

These stones are ground to dust, then mixed with a little (partly recycled) HDPE. This component functions as ‘glue’ for the stone minerals. Due to this combination of resources, recycling of the material becomes infinite. The Calcium Carbonate minerals don’t lose their form, as opposed to pulp paper fibers that do break after recycling and end up as waste in the end.

The heated mix of HDPE and dust pellets, become a texture comparable to a balloon. This mixture can be stretched out very high, and thus as thin as wished for. At the same time the material cools down and can then be rolled up into paper rolls.

2. Why is stone paper more sustainable than pulp paper?

In this chart, you can see the difference in resource usage in production for both stonepaper and virgin – as well as recycled pulp paper.

3. Why did stone paper receive a cradle to cradle certificate?

Stone paper is cradle to cradle certified by the official cradle to cradle Institute. The paper has a silver cradle to cradle label. On the right you can see what valuation was given to different aspects of the paper production.

Cradle to cradle literally means there is no ‘grave’ for the product after it has been used. The material does not need to leave any waste behind after usage, but can be properly recycled.

4. How to recycle stone paper?

Stone paper is made from original stonep powder and can thus be recycled easily.

In theory, stonepaper is infinitely recyclable. If there were a stonepaper recycling stream, we would be able to fully re-use all stonepaper. However, in practice this still works a bit different, mainly due to a lack of sufficient volume for an own recycling stream.

We advise you to throw away stone paper, with plastic recycling (stream 2). This way, the paper can be fully incorporated in an existing recycling stream. The Calcium Carbonate (the stone that is used) is already a common additive to some plastic products and will thus be properly recycled.

Stonepaper will be recognized as a non-pulppaper product in most recycling streams that we know of. It will thus be filtered out with other products that are not recyclable in a paper recycling stream. Then, it will be processed according to the facilities rules. Sometimes this means that it will be burned, or that it will be sorted and used in proper plastic recycling. The stonepaper will in fact be recognized as a plastic-type product.

Just to make sure – we recommend you recycle stone paper with plastic recycling.

5. Will the HDPE in stone paper be replaced with bioplastic?

A lot of research and development is done to continuously improve the sustainability of the stonepaper and its production process.

Tests are being done with bioplastic replacing the HDPE component of the stonepaper. This will most likely be a bioplastic variety that is not made from a food resource, but for example from non-consumable weeds.

At this moment, the HDPE component is made from partly recycled plastic.

|