| Categories | RC Car Battery |

|---|---|

| Brand Name: | FULLYMAX |

| Model Number: | FB7500-45C-11.1V-WB |

| Place of Origin: | China |

| MOQ: | 300 |

| Price: | To be negotiated |

| Payment Terms: | T/T, Western Union, MoneyGram, etc |

| Supply Ability: | 50Kpcs for stacking cell per day, 200Kpcs for winding cells per day |

| Delivery Time: | 3~7 working days for small order, 14~21 working days with cells in stock for mass order, 4~6 weeks for cells out of stock |

| Packaging Details: | color box |

| Model No.: | FB7500-45C-11.1V-WB |

| Model Description: | 3S2P 11.1V 7500mah |

| Burst (10Sec): | 45C |

| Conti. C-rate: | 20C |

| Dimensions(H x W x L ): | 36.6x47x139 mm |

| Weight: | 506 g |

| Hard case /lead wire: | Hard case , lead wires at two corners |

| Wh: | 88.8 Wh |

| Wire Gauge: | AWG10# |

| Wire length: | 100mm |

| Discharge plug: | Dean Style T connector or XT90 plug (Choose the plug you need) |

| Balancer Connector Type: | JST-XHR |

| Company Info. |

| Fullymax Battery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

| Fullymax 3S Lipo Battery 45C 7500mAh 11.1V High Rate Discharge Li-Po Battery with Deans T Plug Hard case lipo 3S Lipo Battery 45C 7500mAh 11.1V High Rate Discharge Li-Po Battery Compatible with professional 1/10 scale and 1/8 scale RC car hobby models, Emaxx, Bandit, Rustler version, Losi, Team Associated, etc. (Only if the voltage, dimension and the plug match, then it will fit). Our battery cells are made of patented constituents of electrolytes, which have excellent performance at low temperature (with high discharge current even under -10℃) and higher discharge rates compared with other general batteries with similar density. By adding special nano-tech materials and using automatic/semi-auto equipments during cell processing, we obtain battery packs with high energy density (up to 230Wh/kg), low internal resistance, long cycle life, and high quality consistency. Meanwhile, a proper amount of Li3V2(PO4)3 added to the anode of our battery packs can effectively decrease the voltage dropping speed at the early stage of the battery discharge procedure, featuring flat discharge curve during normal usage. |

![]() Related Product

Related Product

![]()

For other configurations (without discharge plug) with same cell model, please refer below table.

| Battery pack | Model Description | Hard case /lead wire | Burst (10Sec) | Conti.C-rate | Dimensions | Weight | Wh |

| FB7500-45C-7.4V-WB | 2S2P 7.4V 7500mAh | Hard case , lead wires at two corners | 45C | 20C | 25.1x47x139mm | 348g | 55.50 |

| FB7500-45C-11.1V-WB | 3S2P 11.1V 7500mah | Hard case , lead wires at two corners | 45C | 20C | 36.6x47x139mm | 506g | 88.80 |

| FB7500-45C-14.8V-WB | 4S2P 14.8V 7500mah | Hard case , lead wires at two corners | 45C | 20C | 48.5x47x139mm | 658g | 111.00 |

![]() Product Feature

Product Feature

![]()

- Ultra-high voltage under load, flat discharge curve, excellent performance at low temperature and high discharge rate.

- Excellent Power, Steady Discharge Performance, Light Weight.

- Patented electrolytes and ultrasonic welding ensures

low-resistance, high-reliability and light-weight properties.

- Longer cycle life compared with most standard batteries in the

market.

- Applications: widely compatible with all major brands car models.

![]() Application

Application

![]()

Compatible with professional 1/10 scale and 1/8 scale RC car hobby models, Emaxx, Bandit, Rustler version, Losi, Team Associated, etc. (Only if the voltage, dimension and the plug match, then it will fit).

![]() Packaging & Shipping

Packaging & Shipping

![]()

Regular Safety Packing Or As Customer's Requirements.

Shipping By Sea, Air Or UPS, DHL, FedEx Express.

PAYMENT TERMS

EXPRESS OPTIONS

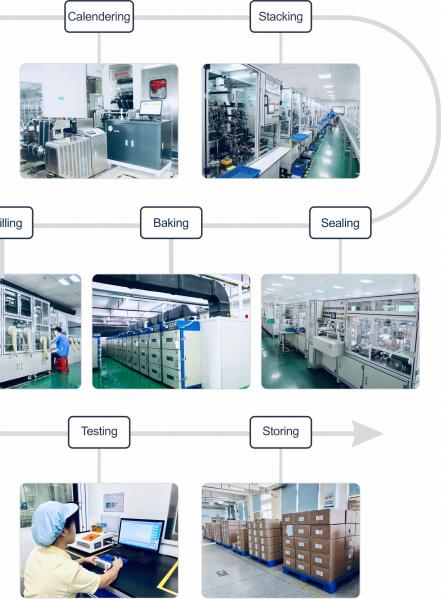

![]() Manufacturing Capability

Manufacturing Capability

![]()

Capacity&Leadtime | |

● Stacking/per day:50Kpcs ● Winding/per day:5,00Kpcs | ● Regular Model:≤8 weeks ● Customized:16-18 weeks(The first order, if nonew facility added ) |

|  |

| The new plant will be located in the Dongjiang Bay Industrial Park, which will be a national high-end industrial park special for new energy, new information technology and intelligent equipment fields based on the “3+7” industrial park planning and deployment proposed by Huizhou relying on the Greater Bay Area, aiming to integrate Huizhou’s “1+4” industrial parks. The area of the new plant is estimated to be 30,000 square meters. With new high-end equipment and workshop environment, the goal is to build a high-end production line dedicated to high-end customers. |

|

| Management Improvement according to international standards |

|  |

|

|

Safety and environmental Certificates capability&service |

|

| Performance Test Capability |

|

![]() FAQ

FAQ

![]()

| Q1.What should be known about assembling battery packs? |

1. Shocks, high temperature or contacts of sharp-edge components

should not be allowed in battery pack assembling process. |

| Q2. What are the diferences betwee high C-rate and low C-rate lithium? |

polymer (Li-Po) batteries. |

| Q3. How is a Li-Po battery made? |

When a Li-Po battery is made, five main aspects should be considered carefully: (1). Battery Pack should have suficient strength, so that the polymer battery inside could be efectively protected from mechanical shocks; (2). The polymer cell should be fixedto the battery pack onits large surface area - no cell movement in the battery packshould be allowed; (3). No sharp edge components should be inside the packcontaining the polymer battery, and meanwhile, suficient insulation layer between wiring and the cell should be used to maintain multiple safety protection; (4). Ultrasonic welding is recommended for polymer tab connection to obtain low-resistance, high-reliability and light-weight properties;(5). Polymer packs shouldbe designed carefully so that no shear force is applied, and also, no heat is generated even when leakage ocurs for mishaps. PCM from electrolyte leakage should be isolated as perfectly as posible, and narrow distance between bare circuit patterns should be avoided. |

| Q4. How to Charge li-Po battery? |

1. Charging Current: Charging current should be less than the maximum charging current listed in specifications. Charging with higher current than recommended may cause serious damage to cell performance and safety features,leading to heat generation or leakage. 2. Charging Voltage: Charging should be performed at a voltage less

thanthat listed in specifications (4.20V/cell). Charging at above

4.25V-the absolute maximum voltage, must be strictly prohibited.The

chargers used should have this voltage limitation function.

Charging with higher voltage than specified is very dangerous,

which may cause serious damage to the cell performance and safety

features, leading 3. Charging Temperature: The cells should be charged within a range of temperatures listed in the specifications. Always let the batteries cool down to ambient temperature before charging. 4. Prohibition of Reverse Charging: Do not reverse the positive(+)

and negative(-) terminals. Otherwise, the batery pack wil be

reverse-charged and abnormal chemical reactions may ocur. Ecesively

high current may flow during recharging, possibly leading to

damage, overheating, smoke emission, bursting and/or ignition. |

| Q5. Why do we need formation process? |

Organic solvents easily decompose on the negative electrodes during charging, leading to battery swelling, drop of cell capacity, and unsafety caused by activereaction. The purpose of the formation process is to form a solid layer called the solid electrolyte interphase (SEl), which is electrically insulating yet provides significant ionic conductivity. This interphase prevents further decomposition of the electrolyte after the second charging. |

| Q6. Why do Li-Po batteries bloat/swell? |

| The Li-Po batteries may bloat or swell due to the following reason: 1. Overcharging:Normally, the maximum charge voltage is 4.2V for RC batteries. If the batteries were overcharged beyond 4.4V, electrolytic oxidation process would happen, which generates mass gas leading to battery swelling. 2. Overheat:When discharging in high temperature or high C rate, the temperature of the inner part of the battery can be even higher, which gasify the electrolyte and results in swelling. 3. Shot-circuit.:If short circuit happened, the cell voltage would drop very fast and the electrolyte would be reactive to generate gases, leading to battery swelling. 4, Sealing:If sealed without proper processing, the battery cell would have water and air in, so that the electrolyte would be reactive to generate gases, leading to battery swelling. |

| Q7.What discharging conditions do you recommend? |

1. We Recommended a cut-off voltage as 3.0 V for standard series

batteries. |

|