| Categories | Carbonated Soft Drink Filling Machine |

|---|---|

| Brand Name: | BIEVO |

| Model Number: | BCG18-18-6 |

| Certification: | CE |

| Place of Origin: | China,Jiangsu |

| MOQ: | 1set |

| Price: | 26500dollers/set |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 10 sets per month |

| Delivery Time: | 30 working days |

| Packaging Details: | wood case |

| Type: | Bottle Filling Machine |

| Name: | Automatic Carbonated Soft Drink Production Line |

| Capacity: | 2000BPH |

| Bottle type: | Glass Bottle crown cap or aluminum screw cap |

| Filling Material: | Beer, Carbonatd Drinks |

| Bottle size: | 200-2500ml (Customized) |

| Machine Size: | 3100*2300*2800mm |

| Weight: | 4000KG |

| Filling temperature: | 2~5degree |

| Advantage: | High Effective |

| Machines material: | Stainless Steel SUS 304/316L |

| Control: | SIEMENS or Mittisubishi |

| Electric parts: | schneider |

| Function: | Carbonated drink Filling And Packing Machines |

| Marketing Type: | Easy to Operate |

| Condition: | new |

| Filling type: | Isobaric filling |

| Washing Heads: | 18Heads |

| Filling Heads: | 18Heads |

| Capping Heads: | 6Heads |

| Company Info. |

| Zhangjiagang City Bievo Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Craft beer or carbonated drink glass bottle beer rinse filling capping machine process plant

Hot sale automatic glass bottle filling production line machines are used to fill whisky, wine, vodka and other non-carbonated beverage.

All the machine part which contact with liquid is high quality stainless steel 304. The relative fittings are from international famous brand.

The automatic glass bottle filling production machines were equipped with suspension type air conveyor and frequency control of motor speed.

This machine is comprised of rinsing, filling and capping system. Rinsing: grip the bottle neck, rotate filling plate, inverse bottle; internal rinsing and external spraying make bottles be cleaned completely. Filling: gravity filling with holding bottle neck; the special backflow type of the filling valve can avoid leakage after filling and also control liquid level accurately. Capping: magnetic torque bottle holding type can minimize the cap damage rate and make the capping performance the best.

This machine owns the reasonable, stable and safe design. Under the condition that the bottle neck size is the same, only the output star wheel needs to be changed if bottles are different. It improves the efficiency a lot.

We are the automatic glass bottle filling production line machines manufacturers in China.

Technical Parameters Of Carbonated Soda Water Filling Machine :

Model (BCGF) | 24/24/6 | 32/32/8 | 40/40/12 | 50/50/12 |

Washing heads | 24 | 32 | 40 | 50 |

Filling heads | 24 | 32 | 40 | 50 |

Capping heads | 6 | 8 | 12 | 12 |

Capacity (BPH) | 5000 | 8000 | 12000 | 16000 |

Power(kw) | 4.5 | 6 | 7.5 | 9.5 |

Dimension (mm) | 3100*2300 | 3800*2500 | 4600*2800 | 5450*3300 |

| *2800 | *2900 | *2900 | *2900 | |

Weight(kg) | 4500 | 5600 | 8500 | 9800 |

Machines Details :

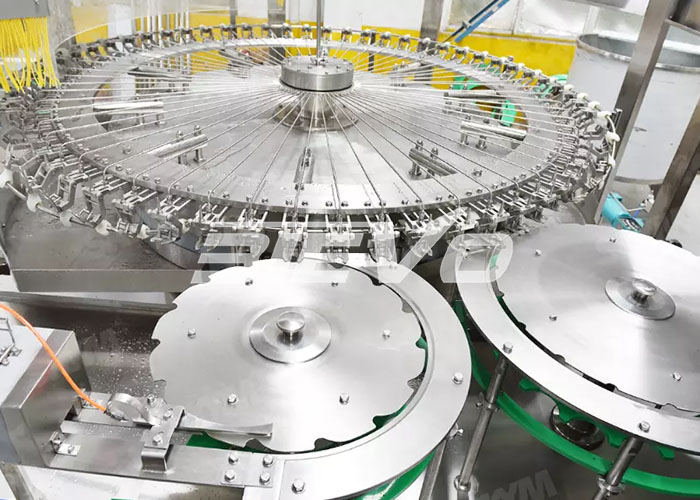

3 IN 1 Carbonated Soft Drinks Filling Machine

Out Look:

> 304 stainless steel frame

> Tempering Glass window, Clear & no odor

> Excellent start wheel design, easy change over parts

> Machine Base with anti-rust process, ensure the forever

antirust

> All seal where liquid may Leakage & base neck come with

rubber, water proof

> Manual lubrication system

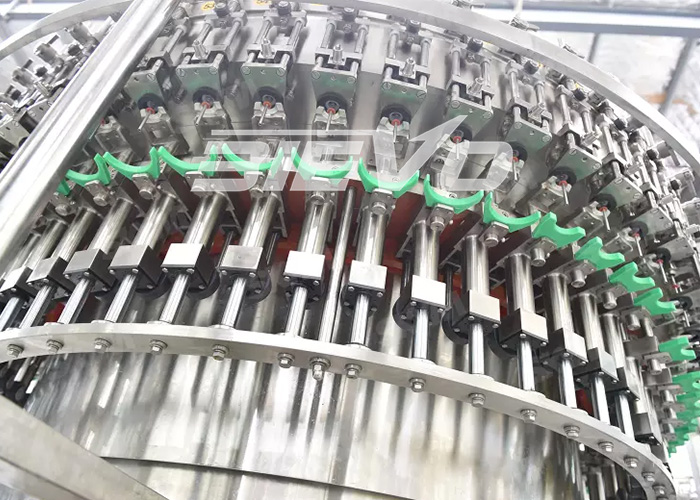

Washing Part:

- Into bottle way is air conveyor direct connection with bottle

dial.

- All 304/316 stainless steel rinse heads, water spray style inject

design, more save water consumption and more clean.

- 304/316 Stainless steel Gripper with plastic pad, ensure minimal

bottle crash during washing.

The three-in-one unit completes the three processes of bottle washing, filling and capping at one time, with little bottle wear, accurate and stable transmission, and convenient bottle type replacement. * The specially designed all-stainless steel bottle washer bottle clamp is sturdy and durable, and does not touch the threaded part of the bottle mouth to avoid secondary pollution of the bottle mouth. * High-speed and large-flow gravity filling valve, fast filling speed, accurate liquid level without liquid loss.

* All parts in contact with liquid are made of high-quality stainless steel materials or food-grade engineering plastics, which meet the national food hygiene standards. * The bottle bottom support plate of the bottle output wheel adopts a spiral descending method, and the height of the bottle conveyor chain is not required to change the bottle shape.

| Technical Partment Of Carbonated Soda Water Filling Machine | |||

S/N | Name | Brand | Country |

1 | Main motor | ABB | Switzerland |

2 | Inverter | MITSUBISHI | Japan |

3 | PLC | OMRON | Japan |

4 | Touch screen | MITSUBISHI | Japan |

5 | Contactor | SCHNEIDER | France |

6 | Thermo- relay | SCHNEIDER | France |

7 | Air-break switch | SCHNEIDER | France |

8 | Proximity switch | TURCK | USA |

9 | Photoelectric switch | BANNER | USA |

10 | Air circuit system | SMC | Japan |

11 | Water pump | Southern | China |

Zhangjiagang City Bievo Machinery Co., Ltd. is located in a national level development zone - Zhangjiagang Economic And Technology Development Zone, covering area more than 8,000 square meters.We enjoy convenient transportation with Shanghai Hongqiao International Airport and Shanghai Pudong International Airport on hand.Which accumulated a great number of China's top technologists in the liquid beverage industry.We have complete system from designing, manufacturing, installation, training to after service.Our main product water production line, carbonated beverage production line . Fruit juice and milk production line ,3 to 5 gallons production line, daily chemical production line and so on.Plat and tube UHT device, CIP system.All the products are sold well.We devote ourselves to the development, research and production of liquid food and beverage filling and packing industry .

![]()

1.Can your factory provide he whole plant from A to Z?

Yes, we can provide the complete plant, from bottling making

plant,water purification plant,to filling packing plant.

2.Are all machinery your factory made?

Our factory make the water purification and filling packing

plants.we do not make the bottle making machinery,we have good

quality bottle making machinery partner,and we provide to customer

same long warranty time and good after service.

3.How can I know the machinery quality before i order?

First,we will invite you visiting our factory to check the machines

quality,and show the machines running for you in our factory.

4.What certificates you can provide?

Our factory provide the CE,SGS,ISO,and according to some

countries,we also can provide the PVOC, COC,SONCAP...etc.

The sample service

1.we can send you the video of the running machine

2.you are welcome to come to visit our company,and see the machine

running in our factory,we can pick you up from the station near our

city.

3.If we get the permission of the customer who has brought the

machines from us ,we can tell you their contact imformation,you can

go to vist their factory.

Customized service

1.we can design the machines according your requirements(materil

,power,filling type,the kinds of the bottles,and so on).

2.we will give you our professional suggestion,as you know,we have been in this industry for many years.

After-sales service

1.we will provide the bill of load on time to make sure you can get

the machine quickly

2.when you finish the Preparation conditions ,our engineer will go

to your factory to install the machine ,and give you the operating

manual ,and train your employee until they can operate the machine

well.

3.we provide one year warranty with spare parts free.

|