| Categories | Industrial Oxygen Generator |

|---|---|

| Brand Name: | SUMAIRUI GAS |

| Model Number: | OSO |

| Certification: | ISO9001, CE, BV, SGS, TUV, ASME, GOST,NB,NR ETC |

| Place of Origin: | SUZHOU, CHINA |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 100 sets/months |

| Delivery Time: | 30-45 days |

| Packaging Details: | Exporting wooden case /Film packing |

| Material: | Mild steel/Stainless steel |

| Purity: | 93%-95% |

| Pressure: | 3-5 bar |

| Capacity: | 10-1000Nm3/hr |

| Type: | Plug and play |

| Twin adsorbers: | Yes |

| Customized: | Available |

| PLC: | S7-1200 |

| HMI: | 7inches |

| Voltage: | 220-575V 50Hz/60Hz |

| Certificates: | CE, ISO, ASME, GOST, KGS, NB etc |

| Color: | Customized |

| Size: | As per actual size |

| Company Info. |

| Suzhou Sumairui Gas System Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

80 Nm3/hr purity 93%-95% oxygen generator plug and play for glass

manufacturing making your own oxygen for operation

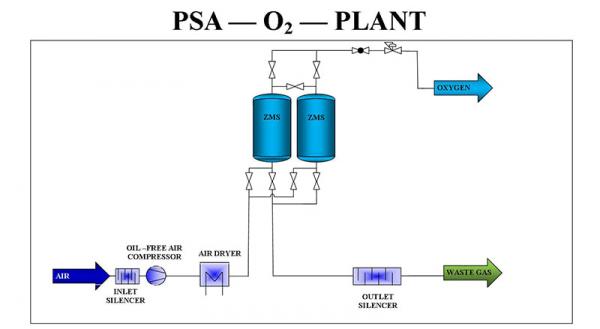

An oxygen generator is a device that separates oxygen from

compressed air using special selective adsorptive technology called

pressure swing adsorption (PSA). The compressed air used in the

oxygen generation process has a similar composition to ambient

environmental air with 21% oxygen and 78% nitrogen. The oxygen

contained in the compressed air is allowed to flow through a

zeolite molecular sieve which retains nitrogen resulting in high

purity oxygen at gas production outlets.

Operating Principles for a PSA Oxygen Generator

The pressure swing adsorption process for a PSA oxygen generator is

essentially the same as that of a nitrogen generator with one major

distinction. The adsorptive material inside its molecular sieve is

made of zeolite rather than carbon found in a nitrogen PSA device.

During a routine operation, compressed air channeled through the

oxygen generator will be separated into its component gases. The

zeolite molecular sieve will selectively adsorb nitrogen that meets

it while allowing high purity oxygen gas to flow onwards to a

product gas outlet.

A unique feature of zeolite that makes it ideal for an oxygen

generator is its ability to released retained nitrogen gas once the

pressure within the generator is eased. This makes it quite easy to

regenerate the medium for a further cycle of oxygen generation.

How Does an Oxygen Generator Work?

An oxygen generator using PSA technology utilizes the ability of

adsorbent zeolite material to separate a stream of compressed air

into its component gases. The pressure swing adsorption process to

produce high purity oxygen is a two-stage cycle that involves

simultaneous adsorption and desorption activities in two generation

towers.

Adsorption

The adsorption stage of oxygen generation uses an adsorptive tower

packed with molecular zeolite pellets that selectively retains

nitrogen while allowing oxygen to pass into a collecting tank as

product gas under pressure.

This process of selective adsorption will continue until the

adsorptive tower reaches its maximum saturation point at which the

zeolite sieve can no longer absorb more nitrogen gas.

Desorption

This second step in the PSA oxygen generation process is

essentially a reversal of the adsorption process. Once the

saturation point for a tower in the adsorptive phase is reached,

its function is altered. Regeneration of the zeolite material is by

rapidly depressurizing the cylinder to release absorbed nitrogen

gas into the atmosphere.

The entire PSA process is automated with a central regulatory unit

detecting oxygen and nitrogen gas saturation levels in both the

adsorption and desorption towers. The phase switch is done by

opening or closing the appropriate process valves and raising or

reducing the pressure within the zeolite packed cylinders.

Features and Benefits :

Turnkey solution

Fully automatic operation

High purity of gas outlet stability

Very competitive production costs

Evolving concept with one or more interconnected production lines

Integrated controller system with high definition color touch

screen

Ergonomic design for simple and economical maintenance

Durable performance thanks to reliable, tested and controlled

components

Low consumption - high efficiency molecular sieve

Technical datas

Purity : from 90 to 99.5% (DS-PSA models)

Flow : from 2 to 150Nm3/h

Inlet pressure : from 7.5 to 10 bar

Applications

Fish farming

Glass Industry

Healthcare / Veterinary

Metal Industry

Water Treatment

Vinification

| Model | Capacity | Purity | Outlet pressure | Inlet | Outlet | Dimensions | Weight |

| OSO5 | 5 |

|

| DN20 | DN10 | 1350*1200*1800 | 800 |

| OSO10 | 10 | DN25 | DN15 | 1800*1250*2200 | 1200 | ||

| OSO15 | 15 | DN25 | DN15 | 2100*1450*2200 | 1500 | ||

| OSO20 | 20 | DN40 | DN25 | 2300*1550*2450 | 1800 | ||

| OSO30 | 30 | DN40 | DN25 | 2450*1650*2550 | 1950 | ||

| OSO35 | 35 | DN50 | DN25 | 2650*1900*2550 | 2150 | ||

| OSO40 | 40 | DN50 | DN25 | 2800*2200*2600 | 2200 | ||

| OSO50 | 50 | DN50 | DN25 | 3100*2450*2700 | 2350 | ||

| OSO60 | 60 | DN65 | DN40 | 3300*2600*2900 | 2550 | ||

| OSO80 | 80 | DN80 | DN50 | 3500*2950*3100 | 3300 | ||

| OSO100 | 100 | DN80 | DN50 | 3850*3100*3300 | 4000 | ||

| OSO150 | 150 | DN100 | DN65 | 4100*3300*3450 | 5100 | ||

| OSO200 | 200 | DN125 | DN80 | 4600*3550*3500 | 6200 | ||

| OSO250 | 250 | DN125 | DN80 | 5500*3900*3900 | 8500 | ||

| OSO300 | 300 | DN150 | DN100 | 5800*4200*3980 | 10500 |

Design reference :

Compressed air inlet pressure 7.5 bar(g)/108 psi(g)

Air quality 1.4.1 according to ISO 8573-1:2010

Oxygen outlet pressure 2-4 bar(g)/58psi(g)

Oxygen quality 1.2.1 according to ISO 8573-1:2010.

Designed working temperature max 50 ℃

Dew point at Oxygen outlet - 50 ℃

Notes:

Following request of oxygen generator will be customized :

Oxygen outlet pressure >4 bar(g)/58 psi(g)

Filling cylinders 150 bar(g)/200 bar(g)/300 bar(g)

Dew point < - 50 ℃

Movable/containerized , plug and play

Other special requirements as per site conditions

|