| Sign In | Join Free | My ecer.com.ru |

|

| Sign In | Join Free | My ecer.com.ru |

|

| Categories | Inconel Alloy |

|---|---|

| Brand Name: | KAIXIN |

| Model Number: | KX-Alloy INx750 |

| Certification: | ISO9001:2015 |

| Place of Origin: | China |

| MOQ: | 200KG |

| Price: | To negotiate |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 50~80 TONS per MONTH |

| Delivery Time: | 45~60days |

| Packaging Details: | Wooden Box, size as per guests' request |

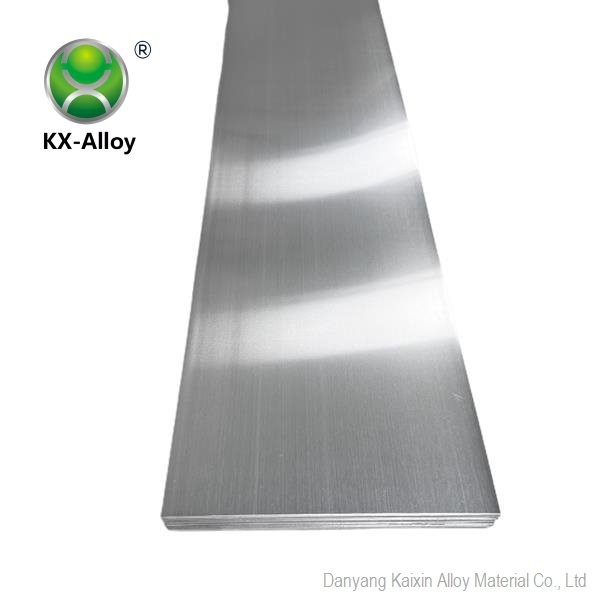

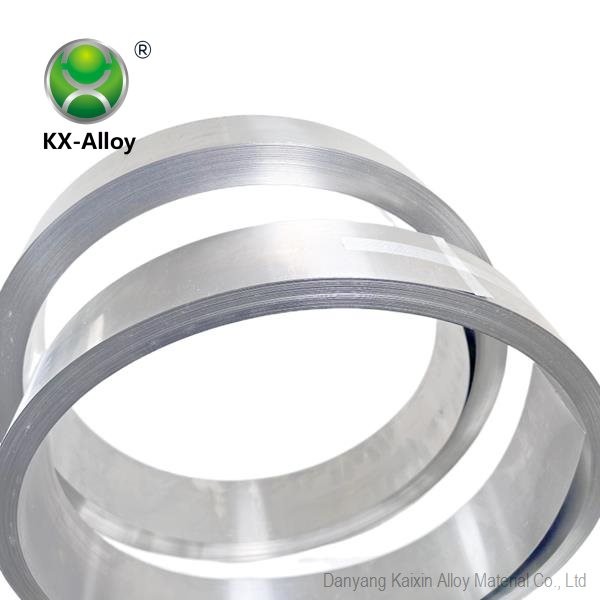

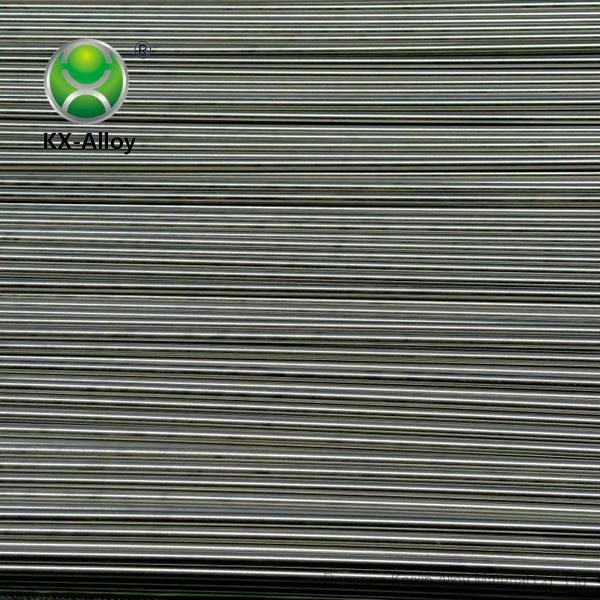

| Shape: | Wire,Strip,Rod,Pipe,Plate |

| Alloy Type: | Nickel Chromium Iron |

| Raw Materials: | NI70%,CR14-17%,NB0.7-1.2%,Ti2.25-2.75% |

| Executive standard: | ASTM |

| Delivery State: | Sosoloid |

| Application: | Can be used to manufacture high-temperature spring, disc spring, bolt, fastener |

| Features: | Corrosion resistance and oxidation resistance |

| Size: | Negotiable |

| Company Info. |

| Danyang Kaixin Alloy Material Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

KX Inconel X-750 Nickel Alloy Wire Round Bar Tube Steel Sheet Light Rod on Inconel Alloy

Product Description and Application

Inconel X-750 Similar name: NiCr15Fe7TiAl(Germany),NC15FeTNbA(France),NCF750 (Japan)

Inconel X-750 alloy is mainly aged strengthened nickel-based superalloy with good corrosion resistance and oxidation resistance below 980℃, high strength below 800℃, good relaxation resistance below 540℃, but also has good formability and welding properties. The alloy is mainly used to manufacture plane springs and helical springs with high strength and resistance to relaxation for aero-engines operating below 800℃. It can also be used to manufacture turbine blades and other parts.

Process Performance and Requirements

Vacuum Induction Furnace(VIM) and Electroslag Remelting Furnace(ESR)

| Alloy | % | Ni | Cr | Fe | Nb | Co | C | Mn | Si | S | Cu | Al | Ti |

| Inconel X-750 | Min | 14 | 5.0 | 0.7 | 0.4 | 2.25 | |||||||

| Max | 70 | 17 | 9.0 | 1.2 | 1.00 | 0.08 | 1.00 | 0.5 | 0.01 | 0.5 | 1.0 | 2.75 |

| Density | 8.28 g/cm3 |

| Melting Point | 1393-1427℃ |

| Alloy | Tensile Strength Rm N/mm2 | Yield Strength RP0.2N/mm2 | Percentage Elongation A5 % | Brinell Hardness HB |

| Solution Treatment | 1267 | 868 | 25 | ≤400 |

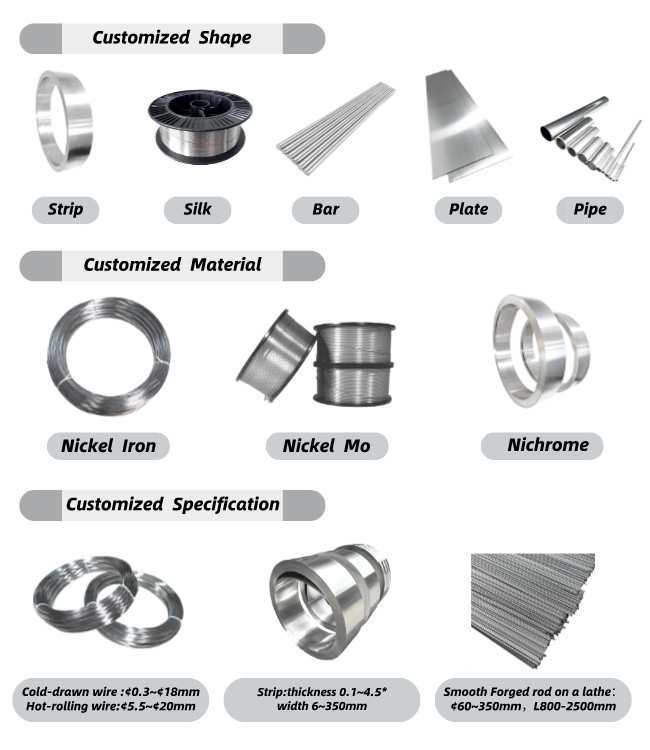

Professional Customization

| Cold-drawn Wire | ¢0.3~¢18mm(Delivery in rolls or trays) |

| Hot-Rolling Wire | ¢5.5~¢20mm(Delivery in rolls) |

| Strip | thickness 0.1~4.5*width 6~350mm(Supply in rolls or straight strips) |

| Smooth Forged Rod on a Lathe | ¢60~350mm,L800-2500mm |

| Hot-rolled Burnishing | ¢20~80mm,L1000-5000mm |

| Cold Drawn and Burnishing | ¢2.5~18mm,L1000-8000mm |

| Seamless Tube | ¢1~275mm,wall thickness 0.2~30,L1000-8000mm |

|