| Categories | Composite Hose |

|---|---|

| Brand Name: | Hongruntong Marine |

| Model Number: | HM-CH12" |

| Certification: | BV, ABS, DNV, LR, SGS, CCS, RMRS |

| Place of Origin: | China |

| MOQ: | 1 Piece |

| Price: | US$250-US$390 |

| Payment Terms: | L/C, T/T, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 550 Pcs Per Month |

| Delivery Time: | 5-7 Work Days |

| Packaging Details: | Wooden Pallets, Wooden Box |

| Name: | Gutteling LNG Hose |

| Material: | First-Rate PTFE |

| Inner Wire: | Galvanized Steel |

| Outer Wire: | Galvanized Steel |

| Inner Lining: | Polypropylene |

| Feature: | Exceptional durability and resistance |

| Standard: | EN13766, EN13765 |

| Diameter: | 1" to 30" |

| Length: | 10m to 40m |

| Connector: | Stainless 304/316 |

| Working Pressure: | 10-21 Bar |

| Vacuum: | 0.9Bar |

| Temperature Range:: | -30℃ to +100℃ |

| Certificate: | BV, ABS, DNV, LR, SGS, CCS, RMRS |

| Color: | Black, Requirements, White, Gray, white and grey |

| OEM: | Warmly Welcomed |

| Usage: | Oil, Chemical, LNG, LPG |

| Warranty: | 36 Months |

| Company Info. |

| Hongruntong Marine LLC. |

| Verified Supplier |

| View Contact Details |

| Product List |

Composite Hose Gutteling LNG/LPG Composite Hose Manufacturers Manufacturing Process

Description

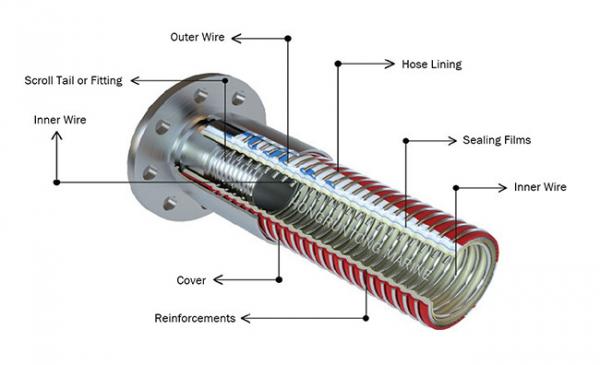

Composite hose, also known as flexible composite hose, is a versatile and efficient solution for transporting various liquids and gases. It is constructed by combining multiple layers of different materials, such as thermoplastic films, fabrics, and inner wires. The innermost layer of composite hose is typically made of a chemically resistant thermoplastic film, which provides a barrier against the transported medium. This layer is reinforced by a layer of fabric, which increases its strength and durability. In addition, an inner wire helix is often incorporated to enhance the hose's flexibility and resistance to pressure.

Composite hoses are highly suitable for a wide range of

applications, including the transfer of petroleum products,

chemicals, and liquefied gases. They are resistant to corrosion,

abrasion, and most chemicals, making them ideal for use in

demanding industrial environments. One of the key advantages of

composite hoses is their flexibility. They are designed to

withstand bending and twisting, allowing for easy installation and

maneuverability. Furthermore, composite hoses are lightweight,

which makes handling and storage more convenient.

To ensure optimal performance and longevity, it is important to

select the right type of composite hose for specific applications.

Factors to consider include the type of medium being transported,

temperature range, pressure rating, and environmental conditions.

In conclusion, composite hoses provide a safe and efficient means

of transporting various liquids and gases. With their reliable

performance, durability, and chemical resistance, they are a

preferred choice for many industries.

Specifications

| Product Name | Composite Hose |

| Inner Wire & Outer Wire | Stainless Steel 316 Stainless Steel 304 Galvanised Carbon Steel Polypropylene Coated Steel Aluminium |

| Inside Lining | Polypropylene P.T.F.E / E.C.T.F.E Poly-amide |

| Layers | Polypropylene Fabrics Polypropylene Films Poly-amide Fabrics Poly-amide Films Polyester Fabrics Polyester Films BOPP Films |

| Outer Cover | PVC Coated Polyester Poly-amide Polypropylene P.T.F.E |

| Max. Elongation | 10% on proof pressure |

| Min. Burst Pressure | 5 x working pressure (Safety factor 5:1) |

| Temperature Range | -30℃ to +100℃ |

| Electrical Resistance | ≤2.5 Ohm/m for under 50mm (2”) ≤1.0 Ohm/m for over 50mm (2”) |

| OEM, ODM | Accept |

| Standard | EN13766, EN13765 |

| Model | Dimensions | Working Pressure | Safety Factor | Bending Radius | Weight | Length | ||

| Composite | [mm] | [inch] | [bar] | [psi] | [kg] | [m] | ||

| HM-CH20 | 20 | 3/4" | 16 | 230 | 5:1 | 80 | 0.8 | 40 |

| HM-CH25 | 25 | 1" | 16 | 230 | 5:1 | 100 | 1 | 40 |

| HM-CH32 | 32 | 11/4" | 16 | 230 | 5:1 | 125 | 1.3 | 40 |

| HM-CH40 | 40 | 11/2" | 16 | 230 | 5:1 | 140 | 1.5 | 40 |

| HM-CH50 | 50 | 2" | 16 | 230 | 5:1 | 180 | 2.5 | 40 |

| HM-CH65 | 65 | 21/2" | 16 | 230 | 5:1 | 200 | 3.3 | 40 |

| HM-CH80 | 80 | 3" | 16 | 230 | 5:1 | 260 | 4 | 40 |

| HM-CH100 | 100 | 4" | 16 | 230 | 5:1 | 380 | 6.8 | 40 |

| HM-CH125 | 125 | 5" | 16 | 230 | 5:1 | 440 | 9.2 | 40 |

| HM-CH150 | 150 | 6" | 16 | 230 | 5:1 | 500 | 13.2 | 40 |

| HM-CH200 | 200 | 8" | 16 | 230 | 5:1 | 750 | 18 | 40 |

| HM-CH250 | 250 | 10" | 16 | 230 | 5:1 | 900 | 26 | 25 |

| *Note: Various sizes can be customized according to the requirements. | ||||||||

Features

Versatility

Composite hoses are designed to handle a wide range of fluids,

including aggressive chemicals, oils, and solvents. Their

construction allows for flexibility and resistance to corrosion,

making them suitable for various industrial applications.

Lightweight and Durable

Composite hoses are lightweight compared to traditional rubber or

metal hoses. Despite their lightness, they are highly durable and

can withstand harsh environmental conditions, such as extreme

temperatures and external abrasions.

Safety Features

Composite hoses are equipped with multiple layers of materials,

including specialized synthetic fabrics, barrier layers, and

helical wire reinforcements. These layers provide excellent

resistance to leaks, ensuring the safety of personnel and

preventing environmental contamination.

Easy Maintenance

Composite hoses are easy to clean and maintain due to their smooth

inner lining, which allows for efficient flow and reduces the risk

of product entrapment. Additionally, they require minimal

maintenance, resulting in cost savings and improved productivity

for the user.

Applications

● Oil and gas industry

● Chemical industry

● Petrochemical industry

● Pharmaceutical industry

● Food and beverage industry

● Marine industry

● Mining industry

● Agriculture industry

● Construction industry

● Waste management industry

Advantages

Extensive Experience

With over 30 years of manufacturing experience, we have gained

valuable knowledge and expertise in producing composite hoses. Our

long-standing presence in the industry demonstrates our ability to

deliver high-quality products consistently.

Specialization in Composite Hoses

Our factory focuses solely on producing composite hoses. This

specialization allows us to concentrate our efforts, resources, and

research on continuously improving product quality, innovation, and

meeting specific customer requirements.

Quality Assurance

We have established stringent quality control measures throughout

the manufacturing process to ensure that each composite hose that

leaves our factory meets industry standards and customer

expectations. From raw material selection to final product

inspection, we prioritize quality at every stage.

Customization Options

We understand that each customer may have unique needs and

specifications. Therefore, we offer flexible customization options

for our composite hoses, including size variations, end fittings,

and specific application requirements. Our ability to tailor our

products according to customer preferences sets us apart from our

competitors.

|