| Categories | Vacuum Paddle Dryer |

|---|---|

| Brand Name: | SENMAO |

| Model Number: | KJG |

| Certification: | CE, ISO 9001: 2008, ISO 10004 |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | 1,400 USD to 285,000 USD |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 30Sets/Months |

| Delivery Time: | 7-15Working Days |

| Packaging Details: | Wooden Case + Plastic Film |

| Type: | Double Shaft Paddle Dryer |

| Application: | Food , chemical , petrochemical , dyestuff , industrial sludge , etc. |

| Condition: | New |

| Brand name: | Senmao |

| Voltage: | customize |

| Power: | variable |

| Dimension(L*W*H): | variable |

| Key Selling Points: | Avoid secondary pollution caused by various sludges |

| Warranty: | 1years |

| Weight(kG): | variable |

| Machinery Test Report: | Provided |

| Video outging inspection: | Provided |

| warranty to core components: | 1Year |

| Mateial: | SUS304,SUS316L,SS304,SS216L |

| Function: | drying and cooling |

| Delivery: | 45-90days |

| Guarantee period: | 1year |

| Package: | wooden case |

| Company Info. |

| Changzhou Senmao Machinery Equipment Co. LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

products descriptions

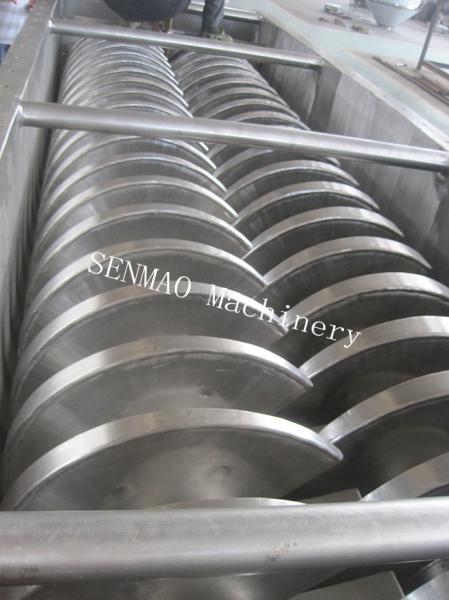

Applicable for drying or cooling of paste, particle, powder and slurry state of material, perform the process of drying, cooling, heating, sterilizing, reacting and combustion under low temperature. The special stirring and heating transferring blade, makes high heat transferring efficiency, and provide self-cleaning function. The special chock shaped stirring and heat transferring blade has high heating efficiency and self-cleaning function of the heating transferring surface.

Hollow wedge-shaped blades are concentrated on the hollow shaft. Heat media flow through the blade from the hollow shaft. The heat transferring area in the effective volume is very high. The temperature range of heating media is -40 ℃ to 320 ℃ . It might be steam, or liquid state, such as steam, thermal oil etc. Indirect heating, there's no heat carried out by air. All heat is utilized for to drying the material except the lost of heat insulation layers. The surface of wedge-shaped blade has self-cleaning function. The relative movements of the product particles and the wedge-shaped surface effects cleaning action, this can clean the material attached to the wedge-shaped surface, so to keep the cleanliness of heat transferring surface during working. The shell of hollow blade dryer is Ω-shaped, and 2 or 4 pieces of hollow stirring shaft are usually equipped in the shell. To avoid any leakage of material or to collect material solvent vapor, there is sealed terminal cover and top cover with the shell. The discharge port is provided with a blocking plate to ensure the material level height, so that the heat transfer surface is fully covered by the material and fully display the surface contribution .The heat transferring media flow through the rotation connector, jacket's shell and hollow stirring shaft. To ensure best transfer effect, the hollow stirring shaft adopts different interior structure in accordance with different heating media.

products Principle

The heat transfer surfaces of hollow paddle dryer included paddle,stirring shaft, and wall surface. And the heat transfer area of paddle is the great majority, so the structure of the equipment is compact and heat transfer area of unit volume is high. Stirring and mixing make the material turnover tempestuously so that the material can get high heat transfer coefficient, the occupied area and space is small and the plant capital cost is saved.Because the structure of the paddle is special, during the during period, material will be extruded and loosed, drying strengthened. Loading ratio of drying chamber is high, it can be 80~90%, drying time can be regulated from a few minutes to a few hours by regulating the feeding speed, the rotary speed of the stirring shaft and the loading ratio. And from feeding port to discharging port the movement of material is basically piston motion. Its residence time distribution is narrow, so the moisture of product is uniform. The paddle on the stirring shaft has a certain axial angle, so it can dry material continuously.

products Features

products parameters

| List of characteristic parameter | ||||||||

| Model | KJG-2.7 | KJG-9 | KJG-13 | KJG-18 | KJG-24 | KJG-29 | KJG-36 | KJG-41 |

| Heat exchange area m2 | 2.7 | 9 | 13 | 18 | 24 | 29 | 36 | 41 |

| Effective volume m3 | 0.06 | 0.32 | 0.59 | 1.09 | 1.53 | 1.85 | 2.42 | 2.8 |

| Rotation range r.p.m | 15-30 | 10-25 | 10-25 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 |

| Power kw | 2.2 | 4.0 | 5.5 | 7.5 | 11 | 11 | 15 | 15 |

| Vessel width A mm | 306 | 584 | 762 | 940 | 1118 | 1118 | 1296 | 1296 |

| Total width B mm | 736 | 841 | 1066 | 1320 | 1474 | 1474 | 1676 | 1676 |

| Vessel Length C mm | 1956 | 2820 | 3048 | 3328 | 3454 | 4114 | 4115 | 4724 |

| Total length D mm | 2972 | 4876 | 5486 | 5918 | 6147 | 6808 | 6960 | 7570 |

| Feed travel length E mm | 1752 | 2540 | 2768 | 3048 | 3150 | 3810 | 3810 | 4420 |

| Central height F mm | 380 | 380 | 534 | 610 | 762 | 762 | 915 | 915 |

| Total height G mm | 762 | 838 | 1092 | 1270 | 1524 | 1524 | 1778 | 1778 |

Air inlet N inch | (2)3/4 | (2)3/4 | (2) 1 | (2) 1 | (2) 1 | (2) 1 | (2) 1 | (2) 1 |

| Water outlet O inch | (2)3/4 | (2)3/4 | (2) 1 | (2) 1 | (2) 1 | (2) 1 | (2) 1 | (2) 1 |

| List of characteristic parameter | |||||||||

| Model | KJG-48 | KJG-52 | KJG-62 | KJG-68 | KJG-73 | KJG-81 | KJG-87 | KJG-95 | KJG-110 |

| Heat exchange area m2 | 48 | 52 | 62 | 68 | 73 | 81 | 87 | 95 | 110 |

| Effective volume m3 | 3.54 | 3.96 | 4.79 | 5.21 | 5.78 | 6.43 | 7.39 | 8.07 | 9.46 |

| Rotation range r.p.m | 10-20 | 10-20 | 10-20 | 10-20 | 5-15 | 5-15 | 5-15 | 5-15 | 5-10 |

| Power kw | 30 | 30 | 45 | 45 | 55 | 55 | 75 | 75 | 95 |

| Vessel width A mm | 1474 | 1474 | 1651 | 1652 | 1828 | 1828 | 2032 | 2032 | 2210 |

| Total width B mm | 1854 | 1854 | 2134 | 2134 | 2286 | 2286 | 2438 | 2438 | 2668 |

| Vessel Length C mm | 4724 | 5258 | 5410 | 5842 | 5461 | 6020 | 5537 | 6124 | 6122 |

| Total length D mm | 7772 | 8306 | 8865 | 9296 | 9119 | 9678 | 9119 | 9704 | 9880 |

| Feed travel length E mm | 4420 | 4954 | 4953 | 5384 | 5004 | 5562 | 5080 | 5664 | 5664 |

| Central height F mm | 1066 | 1066 | 1220 | 1220 | 1220 | 1220 | 1220 | 1220 | 1220 |

| Total height G mm | 2032 | 2032 | 2362 | 2362 | 2464 | 2464 | 2566 | 2566 | 2668 |

Air inlet N inch | (2)11/2 | (2)11/2 | (2)11/2 | (2)11/2 | (2)11/2 | (2)11/2 | (2)2 | (2)2 | (2)2 |

| Water outlet O inch | (2)11/2 | (2)11/2 | (2)11/2 | (2)11/2 | (2)11/2 | (2)11/2 | (2)2 | (2)2 | (2)2 |

Spec | Heat transfer- ring area (m2) | Effective volume (m3) | Range of ro-tating speed (r.m.p) | Power (kW) | Width of vessel A (mm) | Total width B (mm) | Length of vessel C (mm) | Total length D (mm) | Height of center F (mm) | Total height H (mm) |

| QJ3 | 3 | 0.06 | 5~20 | 2.2 | 306 | 736 | 1956 | 2972 | 380 | 762 |

| QJ9 | 9 | 0.32 | 5~20 | 4 | 584 | 841 | 2820 | 4876 | 450 | 838 |

| QJ13 | 13 | 0.59 | 5~20 | 5.5 | 762 | 1066 | 3048 | 5486 | 534 | 1092 |

| QJ18 | 18 | 1.09 | 5~20 | 7.5 | 940 | 1320 | 3328 | 5918 | 610 | 1270 |

| QJ29 | 29 | 1.85 | 5~20 | 11 | 1118 | 1474 | 4114 | 6808 | 762 | 1524 |

| QJ41 | 41 | 2.8 | 5~10 | 18.5 | 1296 | 1676 | 4724 | 7570 | 915 | 1778 |

| QJ52 | 52 | 3.96 | 5~10 | 30 | 1474 | 1854 | 5258 | 8306 | 1066 | 2032 |

| QJ68 | 68 | 5.21 | 5~10 | 37 | 1655 | 2134 | 5842 | 9296 | 1220 | 2362 |

| QJ81 | 81 | 6.43 | 5~10 | 45 | 1828 | 2186 | 6020 | 9678 | 1430 | 2464 |

| QJ95 | 95 | 8.08 | 1~8 | 55 | 2032 | 2438 | 6124 | 9704 | 1560 | 2566 |

| QJ110 | 110 | 9.46 | 1~8 | 75 | 2210 | 2668 | 6850 | 10300 | 1650 | 2668 |

| QJ125 | 125 | 10.75 | 1~8 | 90 | 2480 | 2732 | 7500 | 11800 | 1760 | 2769 |

| QJ140 | 140 | 12.18 | 1~8 | 110 | 2610 | 2935 | 7860 | 12900 | 1856 | 2838 |

Details Image

|