| Sign In | Join Free | My ecer.com.ru |

|

| Sign In | Join Free | My ecer.com.ru |

|

| Categories | Channel Letter Equipment |

|---|---|

| Place of Origin: | Tianjin, China |

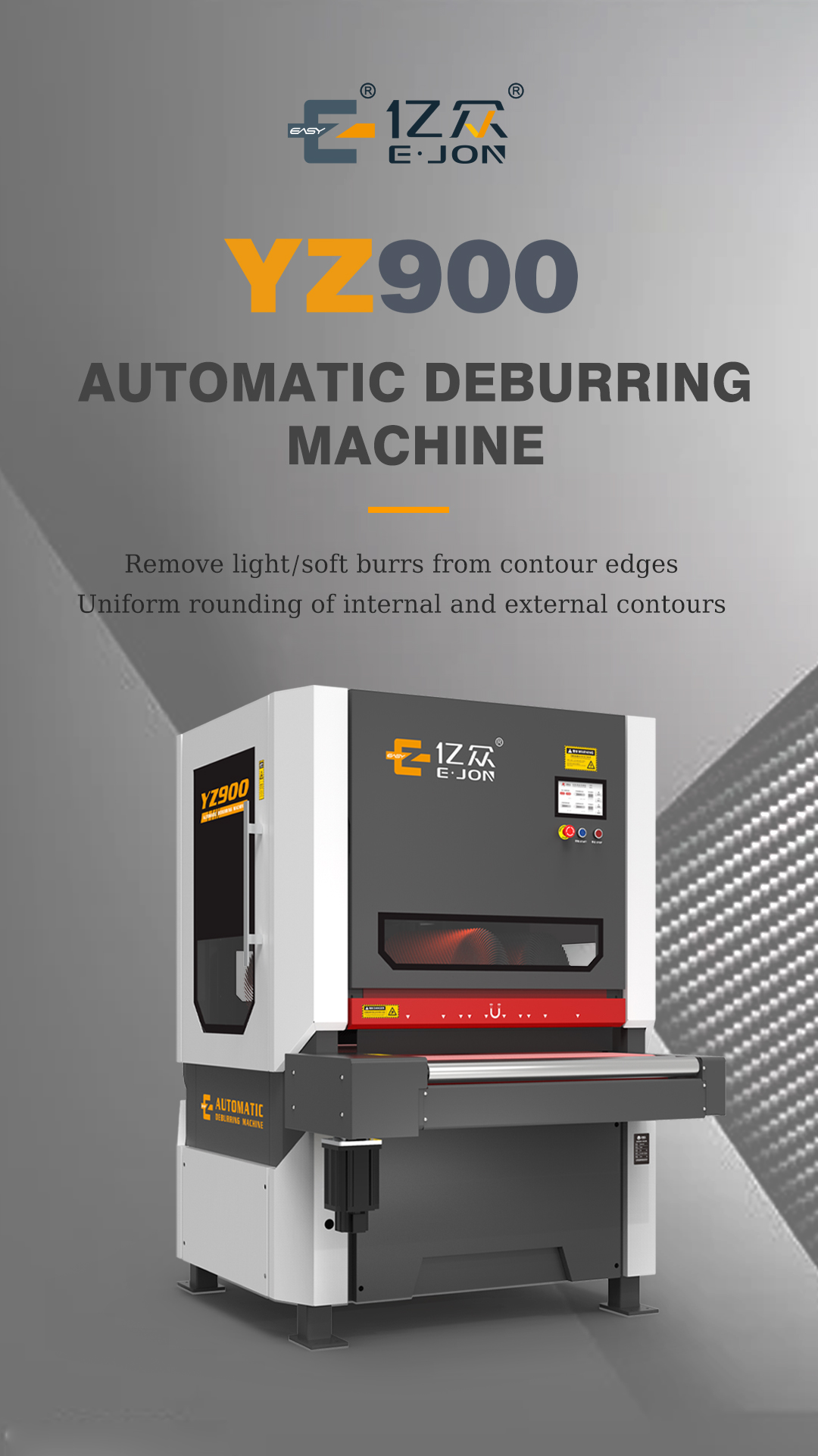

| Brand Name: | Ejon |

| Condition: | New |

| Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided |

| Marketing Type: | Hot selling |

| Warranty of core components: | 1 Year |

| Core Components: | PLC, Motor |

| Power (kW): | 5 |

| Weight (KG): | 1500 |

| Key Selling Points: | High Productivity |

| Warranty: | 1 Year |

| Applicable Industries: | Construction works , Building Material Shops, Advertising Company, Machinery Repair Shops, Manufacturing Plant |

| Showroom Location: | Egypt, Japan, Australia |

| Product name: | sheet metal parts Deburring Machine |

| After-sales Service Provided: | Video Technical Support/online support |

| Application: | Deburring Polishing Chamfer Rust Removal |

| Polishing work piece material: | stainless steel, iron, brass, alloy plate |

| Packing: | Wooden Box |

| Material thickness: | 80 mm |

| Material width: | 1~900 mm |

| Machine size: | 2050mmX1500mmX1900mm |

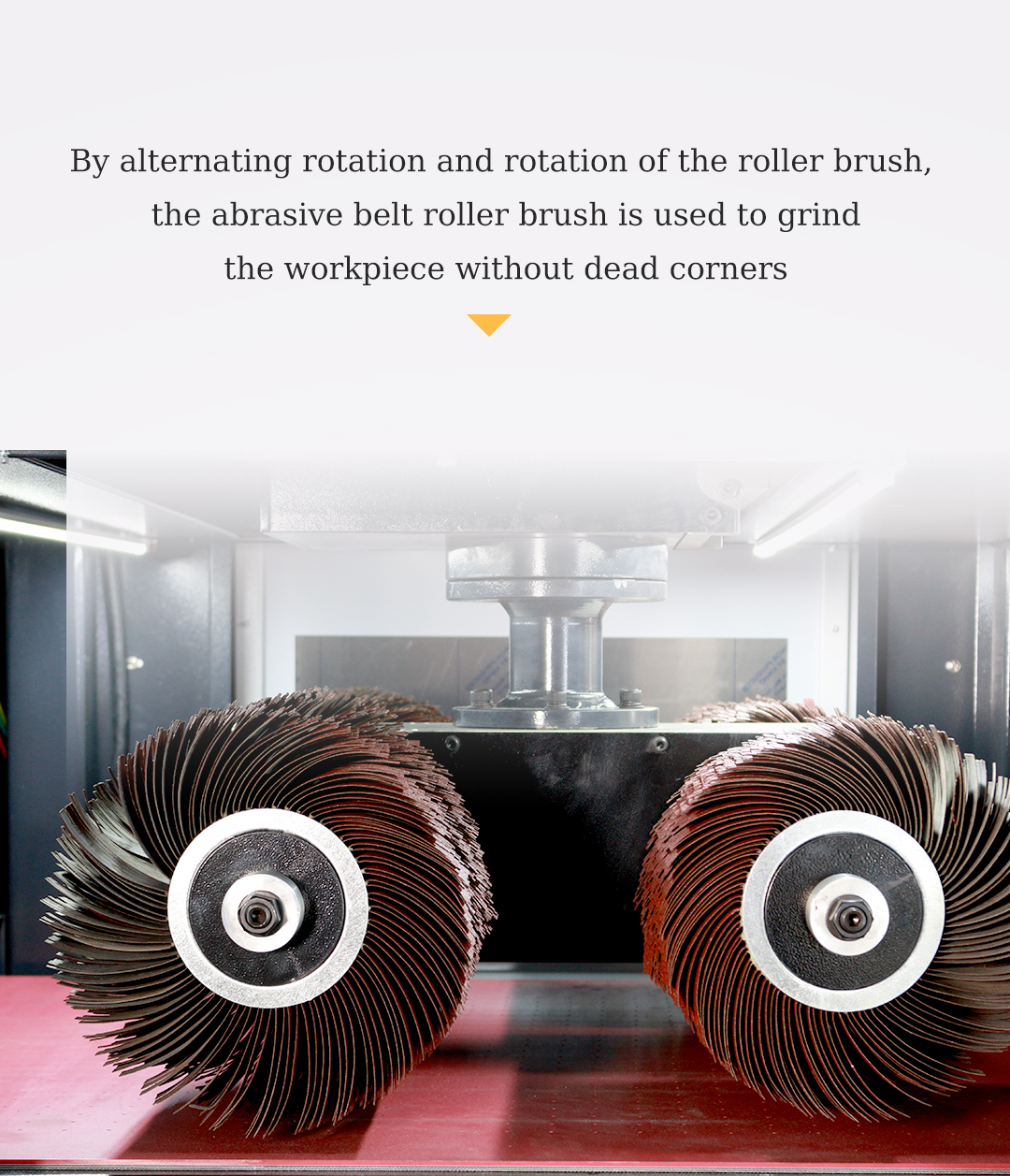

| Spindle Speed: | 0~1000 r/min(Variable frequency adjustable) |

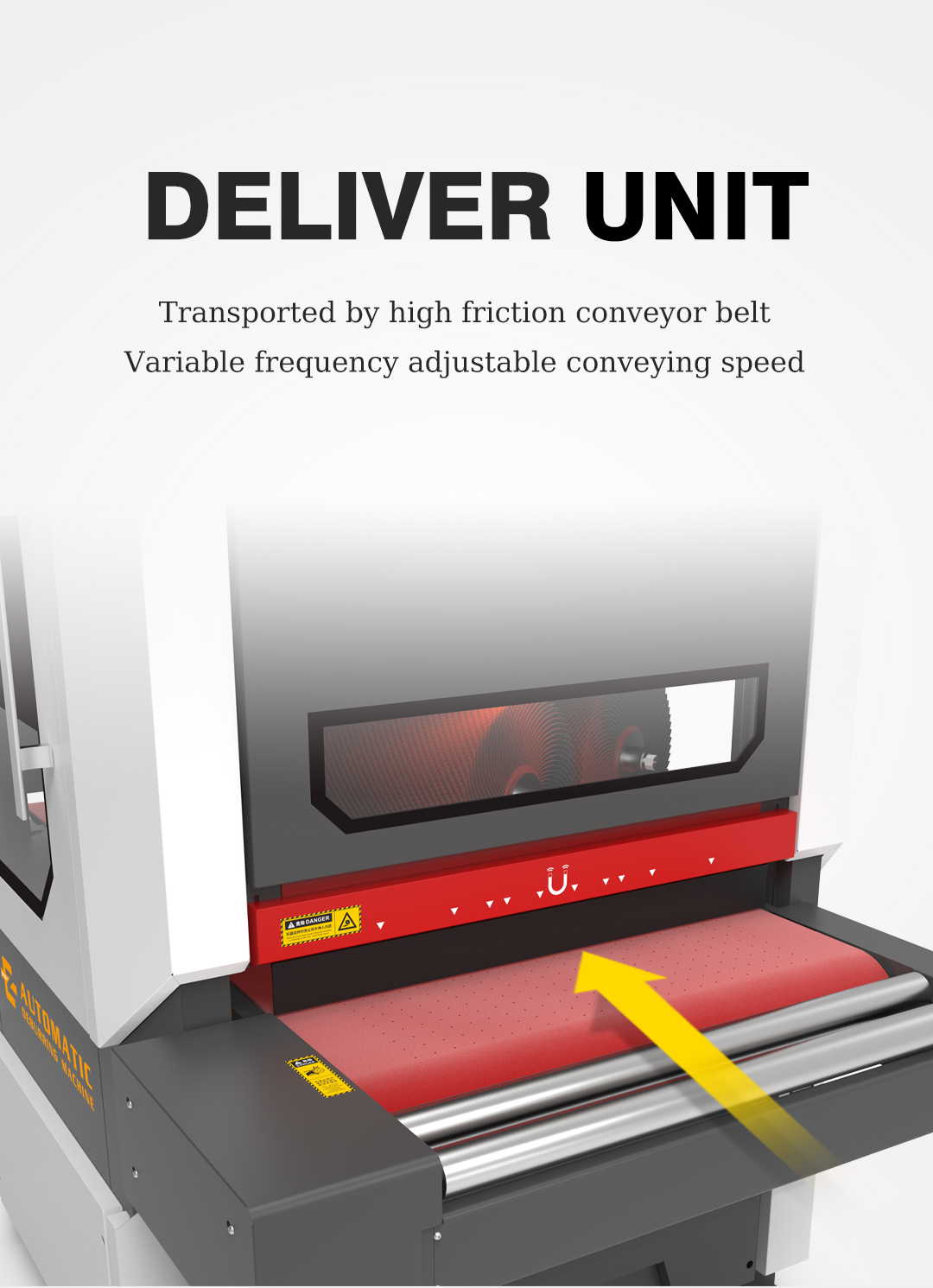

| Transfer speed: | Frequency conversion 0.5-14 m/min |

| Price: | $20,000.00/sets 1-2 sets |

| Company Info. |

| Tianjin Ejon Flying Science And Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

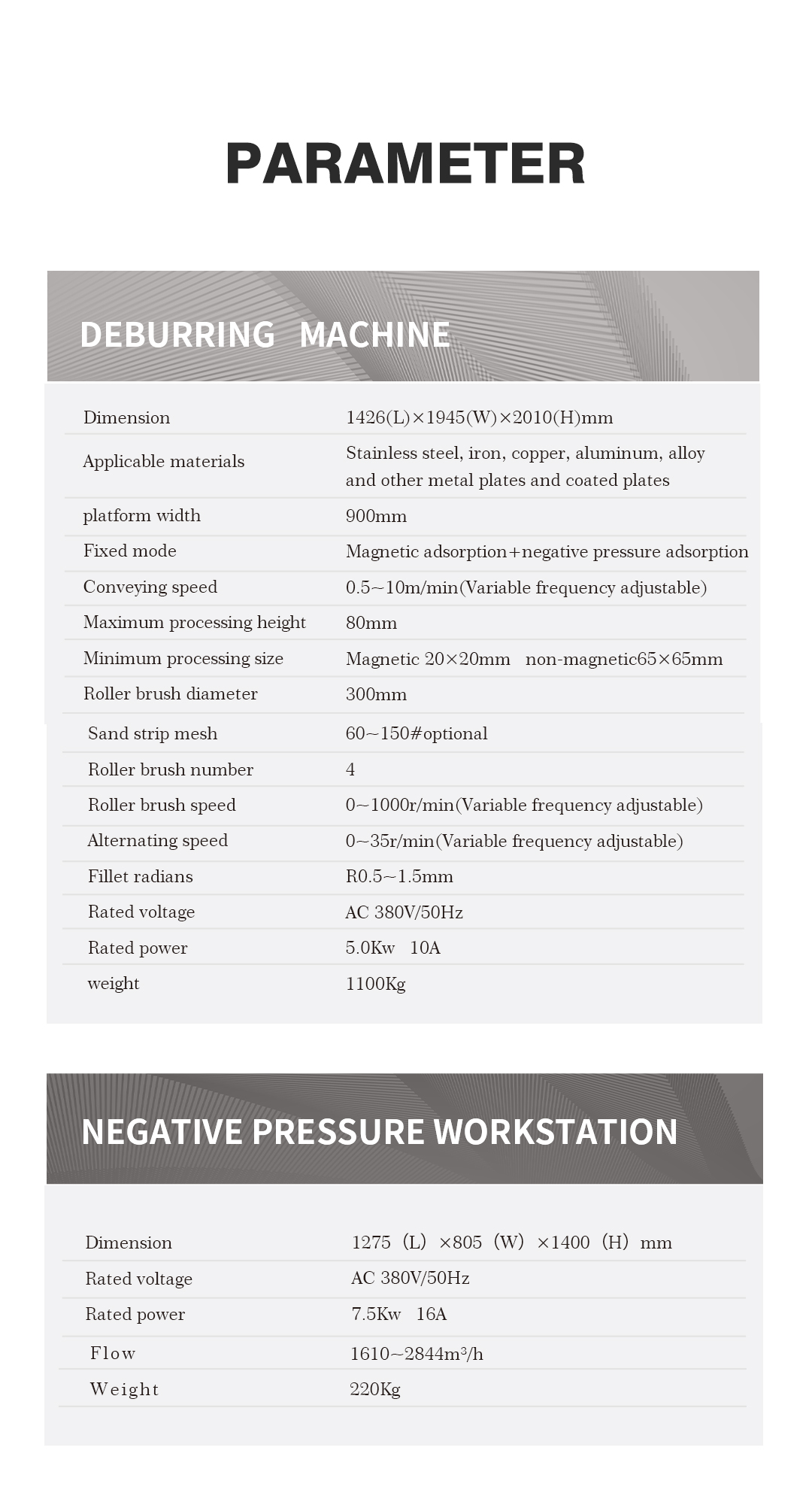

ITEM | DEBURRING MACHINE | DEBURRING & SANDING MACHINE | SANDING MACHINE | DRAWING MACHINE |

MODEL NO. | YZ900, YZ930, YZ1300 | YZ1000S, YZ1000SS, YZ1300SS | SS400, SS630, SS1000, SS1300, SS1500 | LS600, LS1000, LS1300 |

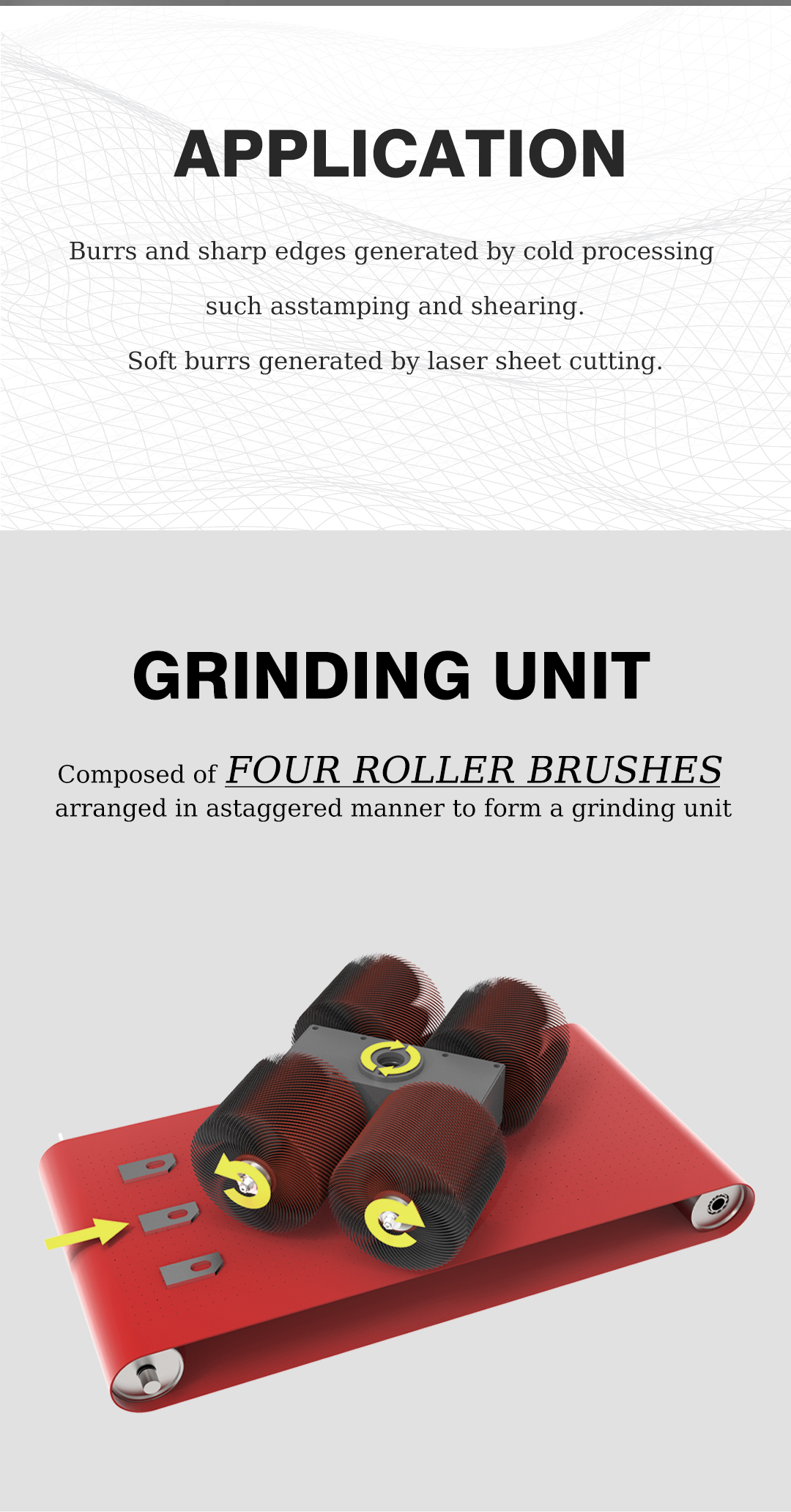

APPLICATION | * Burrs and sharp edges generated by cold processing such as

stamping and shearing * soft burrs generated by laser sheet cutting | * Slag and burr produced by laser, flame, plasma and other hot

processing * Burrs and sharp edges generated by cold processing such as

stamping and shearing | * Laser cutting parts * Stamping parts * Machining parts * Plasma cutting parts | * Can be used for all kinds of wood (oak, pine, elm), and other

wood products * Can be used to process metal (stainless steel, aluminum, iron)

and other deburring, wire drawing lines |

FUNCTION | * Remove light/soft burrs from contour edges * Uniform rounding of internal and external contours | * Remove solid slag and burrs on the surface of the workpiece*

Remove rust and oxide layer on the surface of the workpiece * Uniform rounding of internal and external contours * Hair/snow drawing on workpiece surface | * Grind and remove the slag generated by laser, plasma, and flame

cutting of the sheet metal * Grinding and polishing of oxide and rust scales on the surface of

the workpiece * Workpiece drawing treatment | Take the wood as base material, makes the wood surface have the

effect of texture and groove pattern |

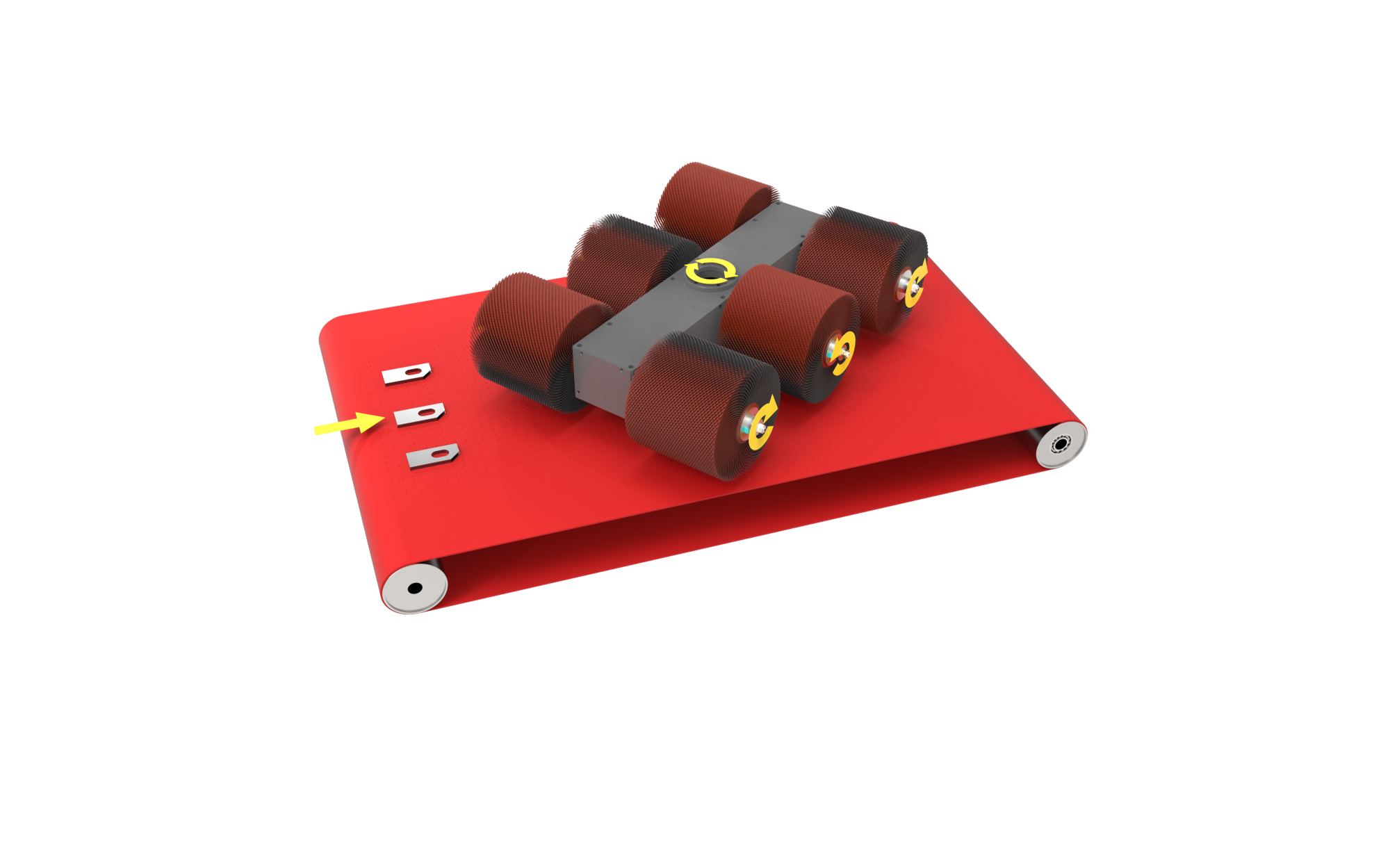

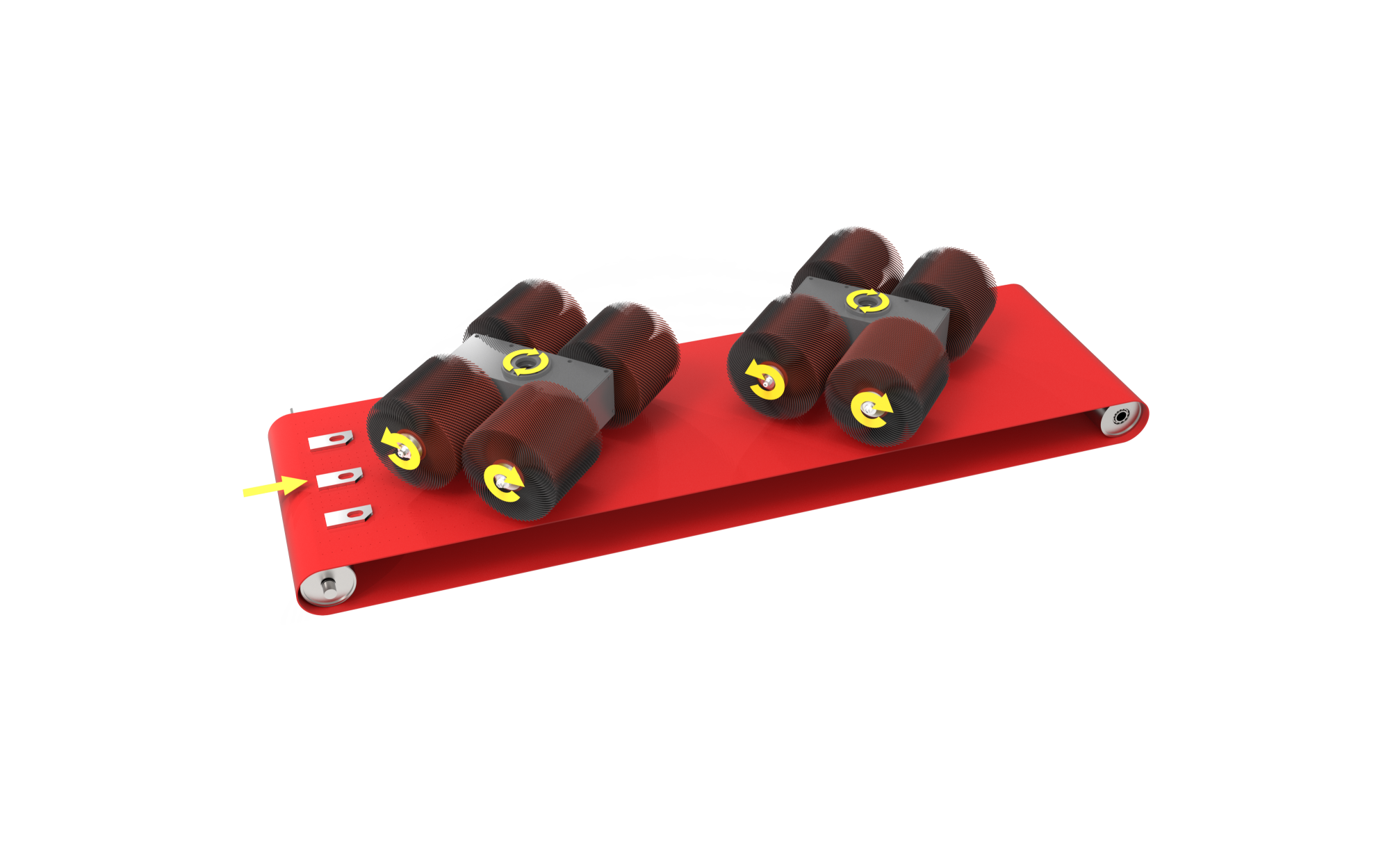

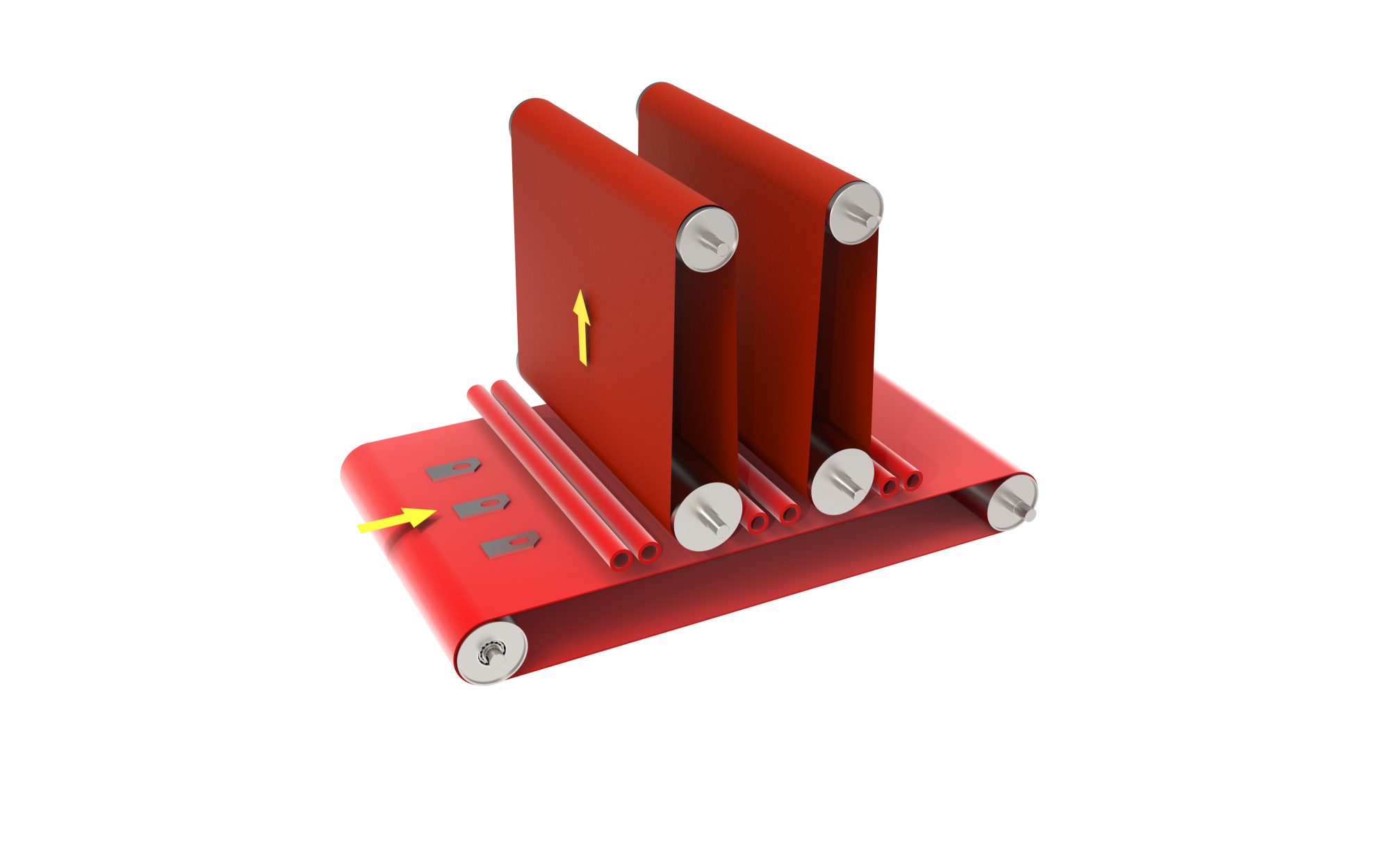

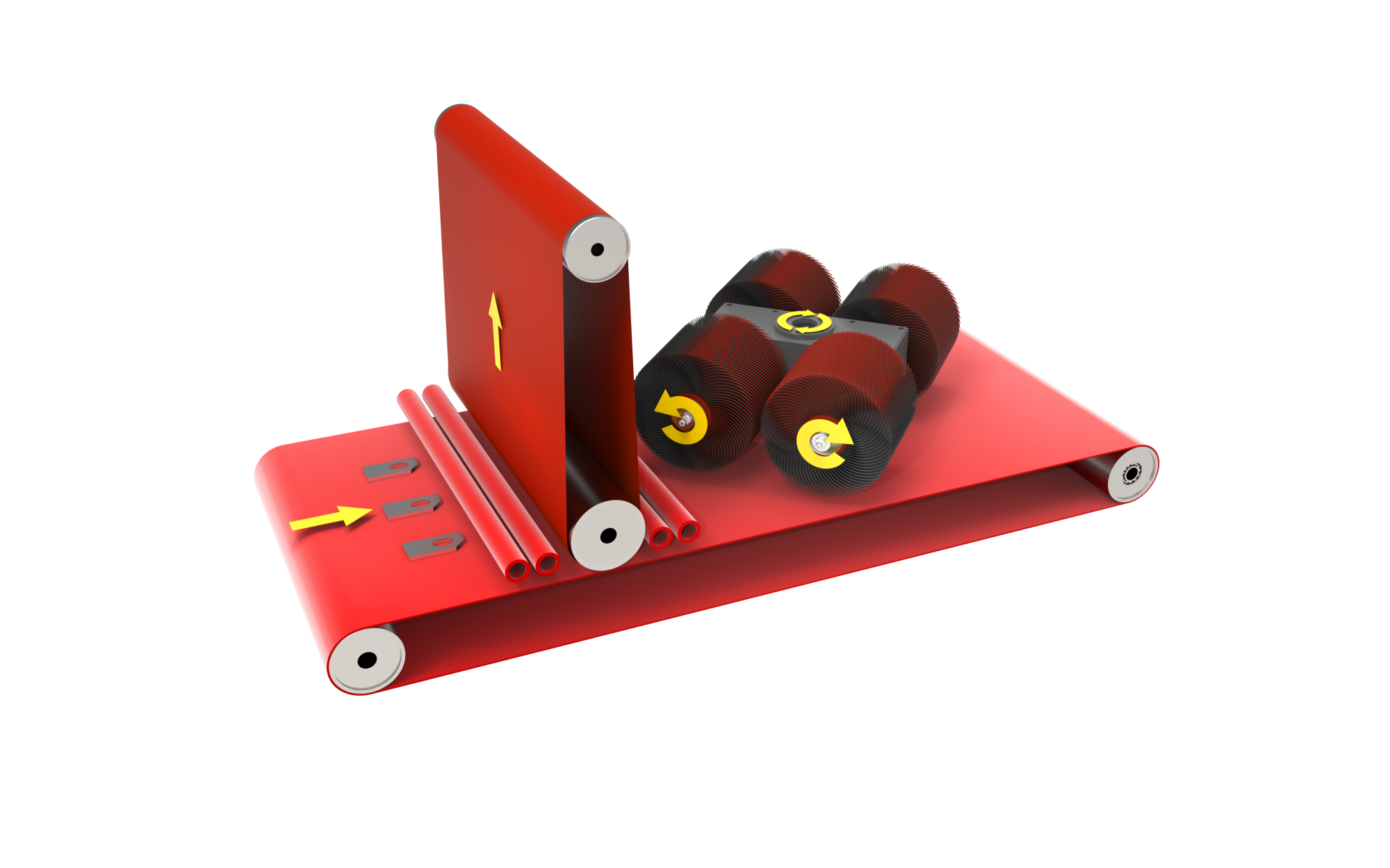

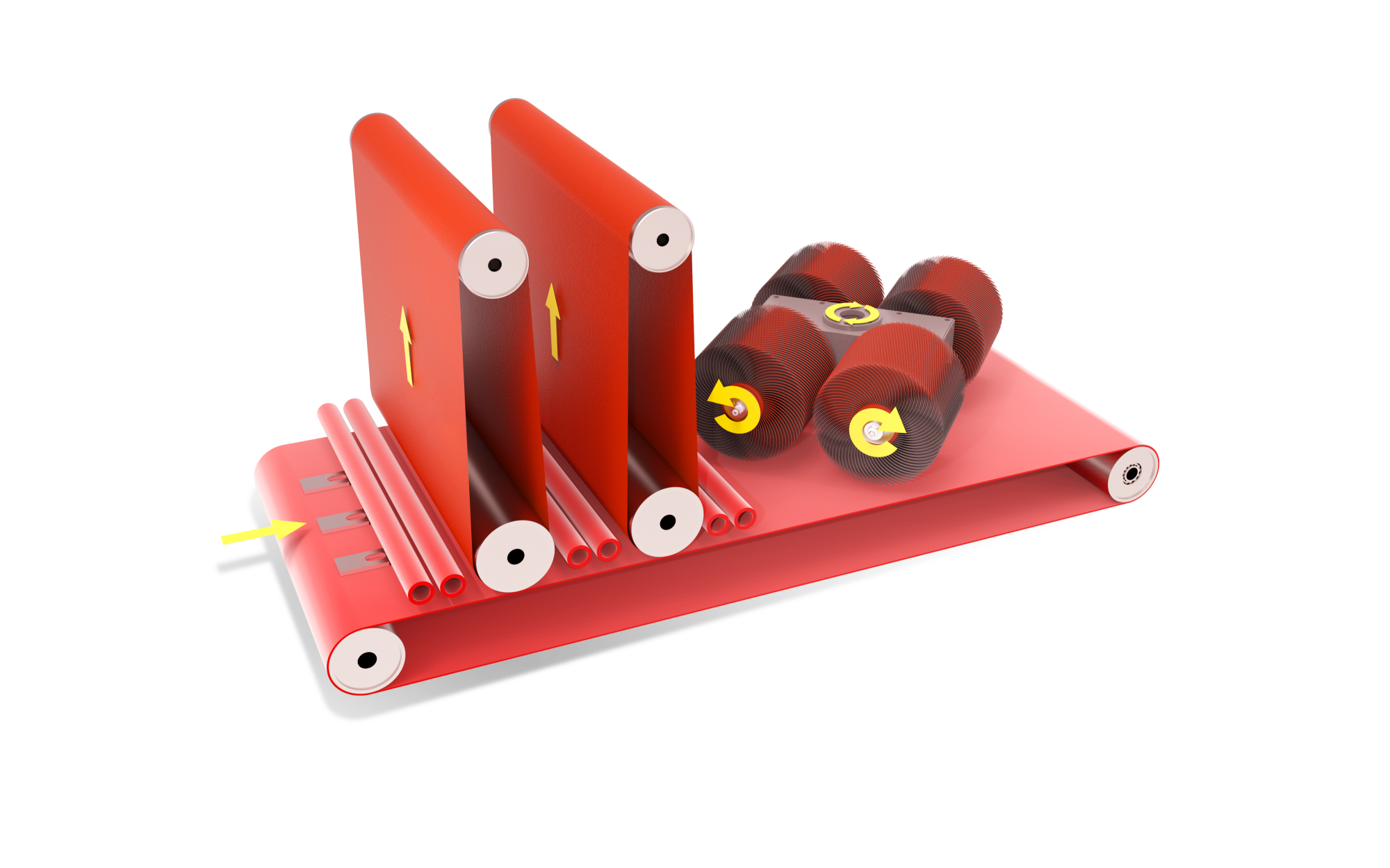

GRINDING UNIT | Roller brushes | Roller brushes + Sand belts | Sand belts | Steel wire roller |

MAX PROCESSING WIDTH | 900mm, 1300mm | 1000mm, 1300mm | 400mm, 630mm, 1000mm, 1300mm, 1500mm | 600mm, 1000mm, 1300mm |

MAX PROCESSING LENGTH | unlimited | unlimited | unlimited | 350mm |

MAX PROCESSING THICKNESS | 80mm | 80mm,50mm | 0.5~110mm | 5~100mm |

|