| Categories | Pipe Bending Machine |

|---|---|

| Brand Name: | LYM |

| Model Number: | DW130CNC10A3S-T |

| Certification: | CE,ISO,BV,TUV,SGS |

| Place of Origin: | CHINA |

| MOQ: | 1 set |

| Payment Terms: | L/C, D/A, D/P, T/T |

| Delivery Time: | 120 days |

| Rated torque: | 57.3kN*m |

| Max bending capacity: | Φ130mm*6mm |

| Bending Accuracy: | ±0.1° |

| Bending arm speed: | 5r/min |

| Max bending radius: | R350mm |

| Tube bending angle: | 0-190° |

| Operation table height: | 1250mm |

| Single feeding length: | 3000mm |

| Dimension: | 7350mm*2800mm*2500mm |

| Weight: | 16 Ton |

| Power: | 86Kw |

| Company Info. |

| Zhangjiagang Liye Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

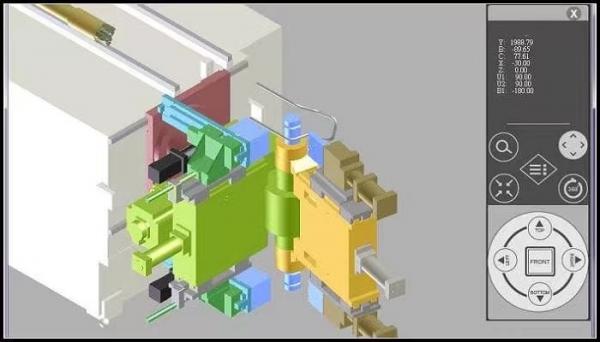

Equipped with 10 electric CNC axes, multiple tube bending stacks, and the unique technology, this line of LYM tube benders can offer one of the highest performance solutions available in the market.

10 Servo Motors

LYM's unique technology

Side positioned bending head/Ultra-thin head and carriage

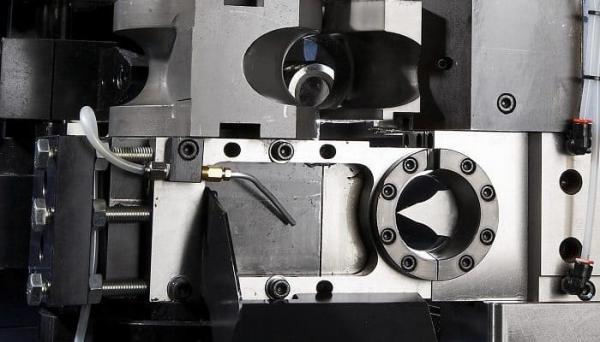

Centralized lubrication for sliding area

Automatic mandrel lubrication

LYM controls software

Single or multi-stacks

Independent pressure die system for each tube bending stack

Wiper die seat and lubrication

Description

| Brand Name: | LYM |

| Model Number: | DW130CNCX10A-3S-T with push bending function |

| Type | CNC CONTROL AUTOMATIC (10 SERVO ) |

| Certification: | CE/SGS/TUV/ISO |

| Place of Origin: | China |

| Application | Pipes or solid bars,various materials such as steel, stainless, aluminum and copper |

| Packaging Details | Packed in stretch film firstly,and then reinforced with plywood for outer packing |

|