| Sign In | Join Free | My ecer.com.ru |

|

| Sign In | Join Free | My ecer.com.ru |

|

| Categories | Industrial Dust Collector |

|---|---|

| Brand Name: | BH |

| Model Number: | BHMC12 |

| Certification: | CE ISO SGS |

| Place of Origin: | China |

| MOQ: | 1 set |

| Payment Terms: | L/C, T/T, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 50 sets per month |

| Delivery Time: | 5-10 days |

| Packaging Details: | Packed into wooden boxes. |

| Name: | High efficiency pulse bag filter BH industrial dust collector |

| Dust Removal: | Pulse Jet Blowing |

| Condition: | New |

| Dimension(L*W*H): | Customized |

| Voltage: | Customized 220V/380V/415V |

| Weight: | Depending |

| Power: | 2.2kw |

| After-sales service provided: | Engineers available to service machinery overseas |

| Company Info. |

| BH Mortar Industrial Co., Ltd. |

| View Contact Details |

| Product List |

High efficiency pulse bag filter BH industrial dust collector

Description:

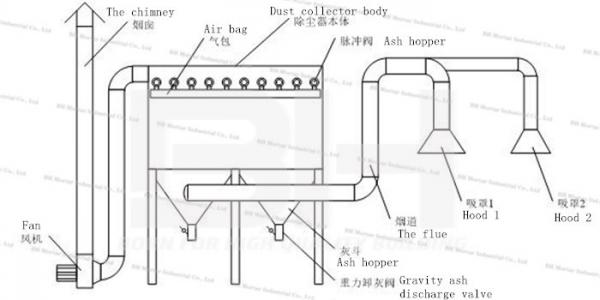

The pulse dust collector is a new high-efficiency pulse dust

collector improved on the basis of bag filter. It combines the

advantages of sub-chamber back-blowing various pulse jet dust

collectors, and overcomes the shortcomings of insufficient chamber

dust-removing strength and uneven distribution of inlet and outlet

winds. Expanded the scope of application.

The pulse dust collector is when the dust-containing gas enters the

dust collector from the air inlet, first hits the sloping plate and

the baffle in the middle of the air inlet and outlet, the air flow

turns into the ash hopper, and the air flow speed is slowed down,

and the coarse particles in the gas are caused by the inertia. The

dust flows directly into the ash bucket. As a function of

pre-collection, the airflow entering the ash bucket is then folded

upwards and collected through the filter bag dust containing the

metal skeleton inside, and is collected on the outer surface of the

filter bag, and the purified gas enters the upper cleaning chamber

of the filter bag chamber, and is collected. When the tuyere is

discharged and the dust-containing gas is purified through the

filter bag, the dust accumulated on the filter bag increases with

time, increasing the resistance of the filter bag, causing the

treatment air volume to gradually decrease, for normal work, to be

controlled. The resistance is within a certain range (140--170 mm

water column). Once the range is exceeded, the filter bag must be

cleaned. When the dust is cleaned, the pulse control device

sequentially triggers each control valve to open the pulse valve.

The compressed air in the air bag is blown by the blowing pipe.

Each hole is sprayed into each corresponding filter bag through the

venturi tube, and the filter bag is suddenly expanded rapidly, so

that the dust accumulated on the surface of the filter bag is

detached, and the filter bag is restored to its original shape. The

dust falls into the ash bucket and is discharged through the ash

discharge system. Thereby, the dust accumulated on the filter bag

is periodically pulsed and cleaned, so that the purge gas passes

normally, and the dust removal system is operated.

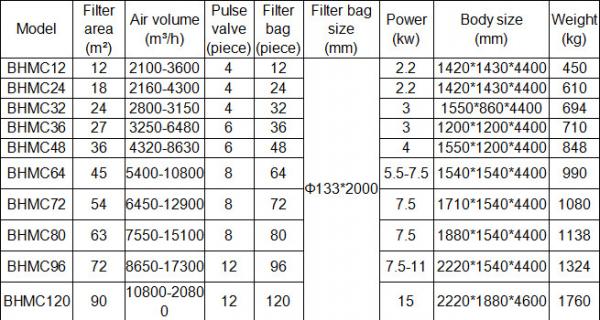

Parameter:

Working principle:

Application:

The pulse dust collector adopts the off-line off-line pulse cleaning technology to overcome the shortcomings of anti-air cleaning and general pulse cleaning. It has strong cleaning ability, high dust removal efficiency, low emission concentration, low air leakage rate and low energy consumption. Less, the operation is reliable and stable. This series of dust collectors is especially suitable for the following occasions: dust removal in calcium carbide furnaces, dust removal in various electric furnaces in iron alloy plants; flue gas purification in steel plants; dust removal in small boilers for coal-fired boilers and power plants; dust removal in waste incinerators; high-temperature flue gas dedusting in smelters; Flue gas purification; cement plant rotary kiln kiln tail, kiln head dust removal; carbon black plant exhaust gas dust removal. Its application area is characterized by high temperature and large smoke volume.

Trouble shooting method:

| Malfunction | Reasons | Remedy |

| Large running resistance | 1 filter bag knot; 2 pulse valve does not work or damage; 3 compressed air pressure is too low; 4 pulse valve operation when the poppet valve is not closed; 5 one or more poppet valves are closed | 1 clean the filter bag, strengthen ventilation; 2 maintain or replace the pulse valve; 3 check the gas circuit and air compressor; 4 check the cleaning controller |

| small running resistance | 1 smoke short circuit; 2 filter bag breakage | 1 Check the pipeline and repair the damage; 2 Check and replace the filter bag |

| The pulse valve does not work | 1 power failure or cleaning controller failure; 2 pulse valve has debris, has been leaking; 3 pulse valve coil burned; 4 compressed air pressure is too low | 1 restore power supply or repair the cleaning controller; 2 carefully clean the pulse valve; 3 replace the pulse valve coil; 4 check the pneumatic system and compressor |

Work site:

|