| Categories | Oxygen Filling System |

|---|---|

| Brand Name: | Chenrui |

| Model Number: | CBO |

| Certification: | ISO9001;ISO9001:2008 |

| Place of Origin: | hangzhou |

| MOQ: | 1 SET |

| Price: | USD$3,000.00--$200,000.00/SET |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 50 Sets per quarter |

| Delivery Time: | Within 45days after recieved advanced payment |

| Packaging Details: | Export Stardard Package |

| Production rate: | 100% |

| After-sales service provided: | Engineers available to service machinery overseas, Field maintenance and repair service, Online support, Video technical support, Field installation |

| Application: | General Industrial Fields, Medical oxygen generation, Metallurgical combustion, sewage treatment, Medical/hospital oxygen generator |

| Capacity: | 3-400Nm3/h |

| Color: | Blue, White/customized hospital psa oxygen generator price, grey or based on required, white or customer request, Darkgray |

| Product name: | PSA Oxygen Generator |

Fill Oxygen Gas Cylinder PSA Oxygen Making Machine , Oxygen Gas Plant

1. Equipment Installation Condition

| oxygen capacity | 3-400Nm3/h |

| oxygen purity | 93%+-3% |

| output pressure | 0.1-0.4MPa(1-4Bar) adjustable / 15MPa filling pressure offered |

2. How it works ?

The raw air will be removed its particle by inlet filter and then be pressurized to about 40Kpa.

The air temperature from the air blower is about 75C, after to be cooled by cooling water, it will flows into one of adsorption tower which filled with adsorber.When the raw air flows from the bottom tower to upper tower, the

nitrogen will be adsorbed, oxygen will be oncentrated at the top of tower and be delivered out as product gas.

When the adsorber almost reaches to saturation, in the action of controller, the valves will be switched, the rawair flows into annotheradsorption tower to adsorb. Saturated adsorption tower will be decompressurized to atmosphere pressure andthen be vacuumized to about -60Kpa,product gas will be introduced into the tower to pruge the adsorption bed, thereby,the adsorber will bedesorbed, and prepare for the next cycle.

The two adsorption towers adsorb and desorb alternately to produce oxygen gas continuously.Raw air shifting from one adsorption tower to another tower is controlled by pneumatic valves, the action process of valves is realized by PLC controller. Centralized control system enables the whole system to work automatically.

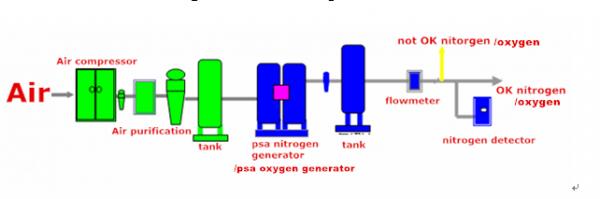

3. Process Flow Brief Description

4. Features:

* Low investment, small workload of construction;

* Low energy consumption, advanced process system;

* High automation, less operators;

* Quickly start, and conveniencely open and shut down;

* Low costs of maintenance;

* Stable operation and highly reliable;

* High quality pneumatic control valves, safe, reliable and durable;

* High quality special oxygen molecular sieve adsobent, good adsorption properties.

|