| Categories | Quality Inspection Machine |

|---|---|

| Brand Name: | KEYE |

| Model Number: | KVIS-G |

| Certification: | NO |

| Place of Origin: | CHINA |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Delivery Time: | 4 to 6 weeks |

| Packaging Details: | Fumigation-free wood |

| Supply Ability: | 1 set per 6 weeks |

| After sale service: | On-line service |

| Core component: | High resolution industrial touch screen |

| False rate: | 0.5% |

| Function: | Quality analyzer |

| Selling points: | Compressed air (non-pollution) |

| Applications: | Automated Aoi Vision System Machine For Duck Feather |

| ODM/OEM: | Yes |

| Loading port: | Shanghai |

Equipment features:

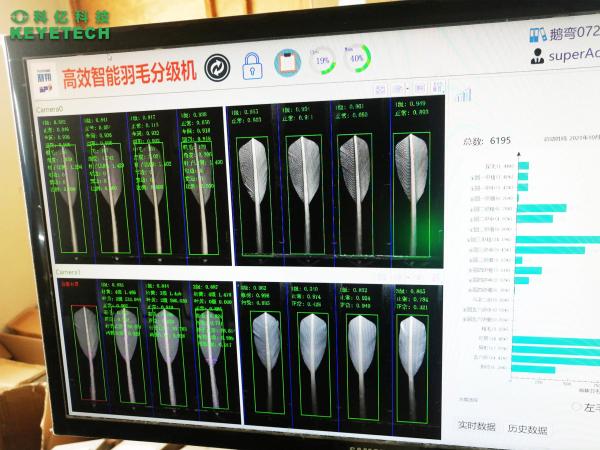

| 1.AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training |

| 2.Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3.Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4.High precision: detection accuracy can be high |

| 5.Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6.Easy to operate: It is easy to operate and easy to maintain |

| 7.Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |

Inspection principle

Badminton is a common sports equipment. In the selection of badminton materials, badminton balls made of duck feathers are favored by many schools and families because of their affordable prices. But before the duck feathers are made into badminton, each duck feather must be cleaned, bleached, dried, and measured. Then classify the duck feather level (level 1, 2, 3, 4, 5, 6), radius, fold printing, trimming and other categories, and place feathers of the same size and angle together.

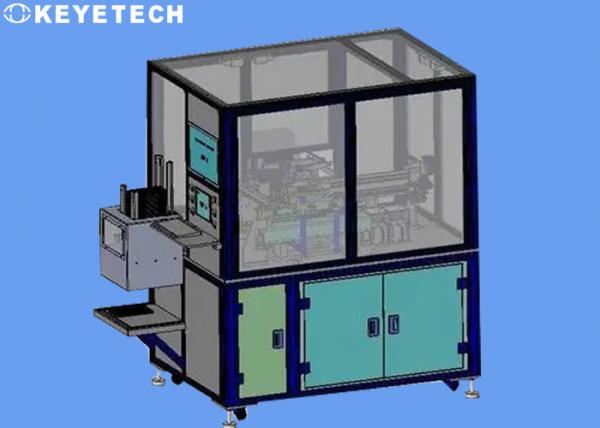

Therefore, the treated duck feathers pass through a sorting machine with 26 sensors, and the airflow of the conveyor belt can blow the feathers into the holes, and then classify the duck feathers according to different detection requirements. The multifunctional duck feather sorting equipment developed by KEYE TECH uses artificial intelligence deep learning to classify duck feathers. It has high detection efficiency and high precision and is compatible with multiple detection requirements. It can effectively replace manual detection, greatly improving detection efficiency.

Traditional image processing algorithms need to design different image processing rules for different scenes. With the increase of scenes, the image processing rules will become more and more complex, and the recognition rate will be lower and lower. The deep learning algorithm used by this machine greatly improves the accuracy of feather classification by training a large number of sample data, which is more efficient than traditional image recognition algorithms. The algorithm has the function of identifying and classifying different types of duck feathers by training different levels of duck feather pictures without adding or modifying the code, and assists in realizing the automation of duck feather detection more efficiently.

| Item | Parameter |

| Voltage | AC220V/50HZ |

| Power | 400W |

| Air pressure | 2-3Kgf/cm2 |

| Speed | 10000 pcs/hour |

| Weight | 200KG |

| Dimension | 130cm×180cm×100cm |

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

|