| Categories | Waste Oil Recycling Equipment |

|---|---|

| Place of Origin: | Sichuan, China |

| Brand Name: | FOREVER |

| Certification: | UL MOTOR if necessary |

| Packaging Details: | TO BE PACKED IN CONTAINER-WORTHY PACKING SUITABLE FOR LONG DISTANCE TRANSPORTATION AND WELL PROTECTED AGAINST DAMPNESS, MOISTURE, SHOCK, RUST AND ROUGH HANDING. INDIVIDUAL PACKING LIST SHALL BE PROVIDED IN EACH SEPARATE PACKING. |

| Supply Ability: | 10 Set/Sets per Year |

| Price: | $200,000.00/Sets >=1 Sets |

| Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Energy & Mining, Recycling |

| Voltage: | customized |

| Power: | customized |

| Dimension(L*W*H): | customized |

| Weight: | customized |

| Warranty: | 1 Year |

| After-sales Service Provided: | Field installation, commissioning and training |

| Product name: | waste oil regeneration system |

| Type: | waste mineral oil |

| Alternative: | oil regeneration |

| Key word: | turnkey project |

| Product Keywords: | complete set |

| Port: | Chongqing/Shanghai, China |

| Company Info. |

| Sichuan Forever Chemical Engineering Technology Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Waste oil regeneration/waste oil regeneration system

The waste mineral oil refers to the mineral oil that has been oxidized, polluted by impurities or affected by thermal interaction, and lost its physical and chemical properties so that has to be substituted. There are various types of common waste mineral oil, such as waste internal combustion engine oil, waste motor oil and waste transformer oil, etc.

Our solution will acquire the raw base oil by evaporating severally and then refining the light components like light bio-diesel, and other raw base oil.

The process applies re-purification combined with refining.

Firstly, we remove solid

mechanical particles and water from the used oil by physical means,

and then we eliminate

light oil from pre-treated lubricating oil by fractionation column.

Finally, we apply advanced

molecular distillation technology on high vacuum condition, so that

we can obtain

regeneration oil which function is close to natural base oil.

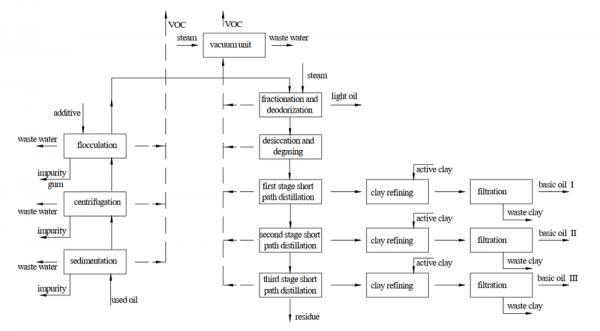

Process description

(1) Pretreatment unit

The pretreatment is necessary for most used oil recycle. Firstly,

the most water and

mechanical impurities was roughly removed by natural sedimentation

for some time at

special temperature, and then we use the centrifugation separator

to remove more water

and impurities before the used oil is sent to next unit. If the

used oil is very bad, we will use

the flocculation to remove some gum, pitch and reduce the acid

value.

(2) Distillation unit

This unit is the core process. Firstly, in order to get good

quality base oil, the pretreated

oil is sent to one or two special tower, the odor and light oil is

removed by these towers, and

then the oil is sent to flash vessel at high vacuum before short

path distillation in order to

remove surplus volatile compound. We normally use two or three

short path distillatory to

get several base oil which viscosity degrees is also different, of course, there are different

operating vacuum and temperature in each short path distillatory,

we suggest three stage

short path distillatory should better be used in your plant in

order to get high product yield at

10,000 TPA throughput capacity.

(3) Clay refining unit

The different base oil form distillation unit is sent dividedly to

different decolourization

vessel which is operated at special temperature and vacuum, and

some active clay will be

added into vessel depending on the quality of input base oil, after

some time, the base oil

with active clay is sent to filtration machine, and then we get the

final base oil with good

color and stable quality.

Poject in Saudi Arabia

Project in Zibo, Shandong, China

Project in Malaysia

Sichuan Forever Chemical Engineering Technology Co., Ltd. was established in 2004 with a registered capital of 35 million RMB, and held by Sichuan Forever Investment Holding Group Co., Ltd., The company is a military-into-civilian high-tech enterprise specialized in R&D, designing, manufacturing, and selling of intellectual equipment and process design of separation technology in chemical engineering projects, as well as general contracting.

With the newly separation technology, we have been able to accomplish the research and process development of liquid mixture separation crafting technologies such as molecular distillation, falling film evaporation, high-efficiency rectification, multi-effect evaporation, MVR distillation, supergravity distillation and vaporization membrane/film distillation, etc. Meanwhile, we have successfully developed the process crafting package and industrial integrated application solutions with proprietary patent rights, in sections like LCD panel stripping liquid regeneration, isopropanol aqueous solution distillation, methanol aqueous solution distillation, waste mineral oil regeneration, Fischer-Tropsch wax refining, fish oil ethyl ester refining, harmless treatment of high-toxic organic wastewater and the bio-diesel producing.

We adhere a tradition from our past as a military enterprise, and that is the “make perfection more perfect” principle. Besides, with the advanced and reliable production quality control systems and highly competent staff teams, as well as the rich experience of industrial application and engineering project implementation, we are capable of offering a range of products and services with proprietary patent rights. Those of which include the core/main equipment, laboratory device, complete set of project equipments and turnkey plant that can be widely used into electronic waste solvent disposal and regeneration, waste mineral oil comprehensive utilization and material separation and refining, etc.

|