| Sign In | Join Free | My ecer.com.ru |

|

| Sign In | Join Free | My ecer.com.ru |

|

| Categories | Juice Filling Machine |

|---|---|

| Brand Name: | Aquatrin |

| Model Number: | RCGF |

| Certification: | ISO CE |

| Place of Origin: | China |

| MOQ: | 1unit |

| Price: | USD12000-50000 1Set |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10units per month |

| Delivery Time: | 45days |

| Packaging Details: | wooden package |

| Keywords: | bottle filling machine |

| Processing Types: | Automatic Bottle Filling Sealing Machine |

| Key Selling Points: | Easy to Operate |

| Warranty of core components: | 2 years |

| Bottle type: | PET, Glass, Plastic |

| Diameter: | 300ml-2000ml |

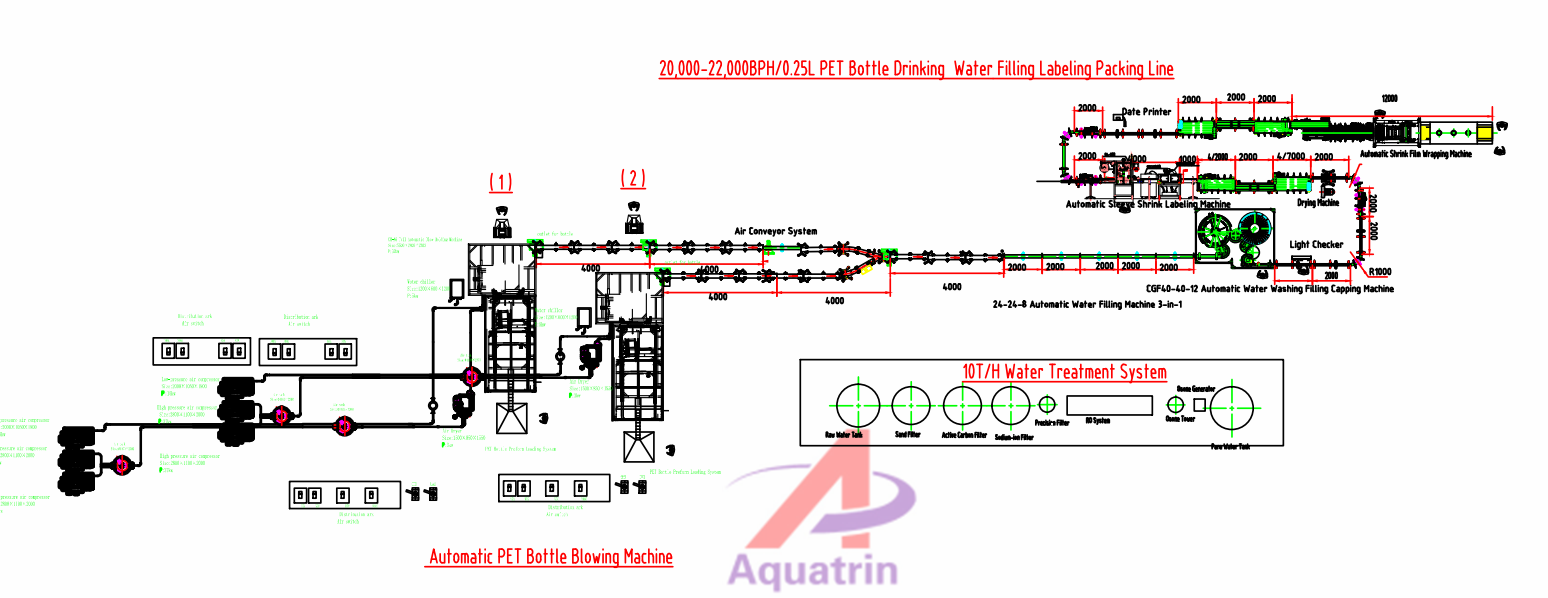

We suplly Free Factory Layout design

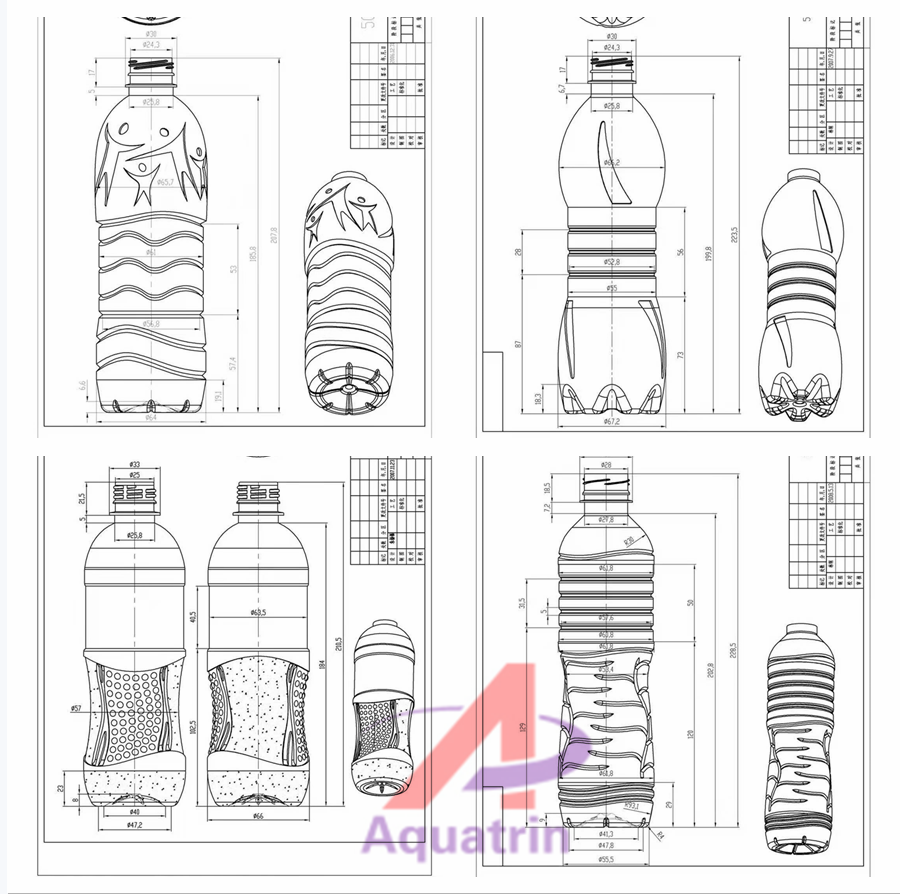

We suplly Free Bottle Shape design

Water treatment system

Labeling Machine

Laser date printer

PE film wrapping package machine

|