| Categories | Extrusion Blow Molding Machine |

|---|---|

| Brand Name: | MEPER |

| Model Number: | MP80FD |

| Certification: | CE/ISO9001:2008 |

| Place of Origin: | NINGBO,CHINA |

| MOQ: | 1 Set |

| Payment Terms: | L/C, T/T |

| Delivery Time: | 25-55 Work Days |

| Packaging Details: | Wooden pallet(Standard) Wooden case(Optional) |

| Container Capacity: | 3LX2 |

| Applicable Material: | PP,ADHENSIVE,EVOH,ADHENSIVE,REPP |

| Multi-layer: | 1-6 layer |

| PLC: | B&R |

| Station: | Double Station |

| Product: | lubricant Bottle |

| Company Info. |

| Ningbo Qiming Machinery Manufacturing Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

High speed Lubricant Bottle Extrusion Blow Molding Machine

Brief introduction

Mold clamping structure adopting advanced four shafts to clamp the mold ,Can clamp the mold firmly ,stable and reliable ,central mold platen is provided with protruding structure ,binging convenience to installing and dismantling molds, making the design human friendly

Piling out system adopting high performance transducer to drive ,saving power by above 30%,can be equipped with 100points wall ,thickness control ,Adopting foreign famous brand MOOG, improving the uniformity of the finished products ,lowering the weight of the finished products ,Flow and pre-sure proportional control valve. consuming less power ,high output ,of high performance price Ratio.

With self-functioned and stable PLC control system ,as well as the integrative of the machine ,electric devices and hydraulic digital controlled and temperature control of PID have been achieved ,The equipment’s operation speed and stability have been greatly improved ,Friendly operational panel ,easy, convenient

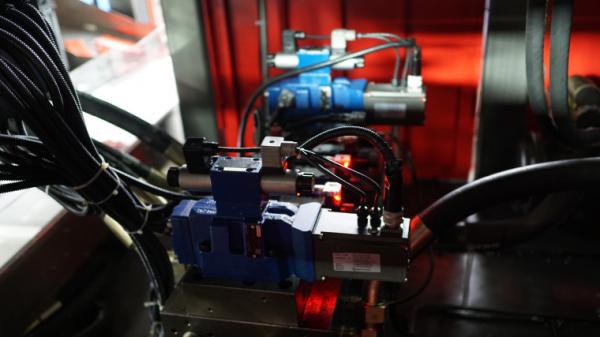

Hydraulic system

Mould opening, closing, rack placing, pen inserting and lifting of this machine are achieved by hydraulic control. As to working process and action principle of hydraulic system, please refer to principle figure of hydraulic system(see Figure1.4) and function introduction.

1. System structure: It is made up of oil pump motor, oil pump, valve plate, oil valve, cooler, oil tank and oil cylinder.

1) Oil pump V4 single pump: When oil cylinder need rapid action, oil pump will supply sufficient oil by high pressure. When oil cylinder need slow action, oil pump will supply little oil by low pressure.

2) Electro-hydraulic proportion overflow speed regulating valve(PQ valve) V10: Regulate pressure and flowrate to satisfy working pressure and speed of different oil cylinders. Regulating methods: Modify some parameter of some action on computer, e.g. changing figure of “high pressure mould clamping” from 100 to 120 will increase mould clamping force (watching pressure guage V8). Speed can be regulated in the same way. The highest working pressure of this system is set at 140kgf/cm2(14Mpa).

3) Electromagnetic reversing valve V11 & V16: Can change the direction of oil cylinder movement.

| Parameters | MP80FD |

| Material | PE PP PVC PA… |

| Max container capacity | 10L |

| Number of die | 1,2,3,4,6 |

| Machine Dimension(LxWxH) | 3.3x5.5x2.8m |

| Total weight | 12ton |

| Clamping force | 150kN |

| Platen openning stokes | 240-620mm |

| Toggle stokes | 600mm |

| Max mould size(WxH) | 550x430mm |

| Screw diameter | 80mm |

| Screw L/D ratio | 24 L/D |

| (HDPE) Plasticizing capacity | 108kg/h |

| Screw heating zone | 4 zone |

| Screw heating power | 15.6kw |

| Screw fan power | 0.14kw |

| Extrusion motor power | 30kw |

| Die head heating zone | 8 zone |

| Power of die heating | 10.3kw |

| Total power of machine | 92kw |

| Power of oil pump motor | 31kw |

| Air pressure | 0.6-0.8 Mpa |

| Average energy consumption | 61kw |

| Consumption compression air | 1.2m³/min |

| Consumption cooling water | 80L/min |

Standard Features:

Auto Lubrication

Water Cooled Modular Blow Pin

Hot Wire Cutting

Positioning Hole For Quick Mold Change

Adjustable Die head

Linear Transducer

FRL(Filter Regulator Lubricator) for Pneumatic

Proportional Hydraulic System fro better control

Swing and Adjustable Extrusion Platform

|