| Categories | Die Steel |

|---|---|

| Brand Name: | Guangda |

| Model Number: | NAK80 Tool And Mold Steel |

| Certification: | DNV, BV, Rina, ISO, GL, ABS, LR,CCS |

| Place of Origin: | China |

| Payment Terms: | T/T, L/C, D/P, D/A |

| Delivery Time: | 15-45 work days |

| Product name: | NAK80 Tool And Mold Steel |

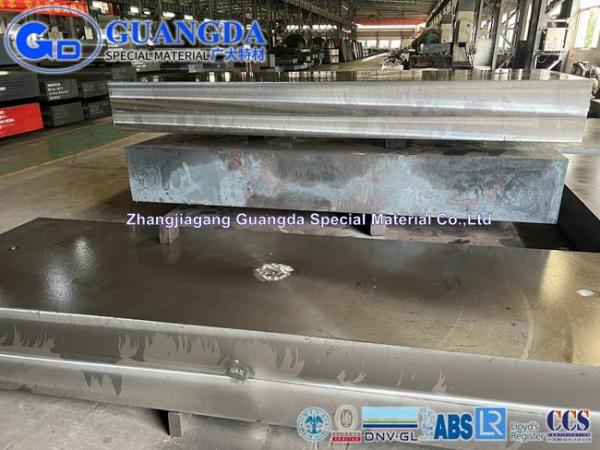

| Shape: | Round bar, Plate, Flat bar, Square, Forging Ring |

| Type: | Forging |

| Supply conditon: | Rough Material ,semi-finished ,finished Machining |

| Material: | NAK80 |

| Smelt method: | EAF+LF+VD+ESR |

| Company Info. |

| Zhangjiagang Guangda Special Material Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

HM NAK80 Tool And Mold Steel Mirror Plastic Die Steel 40HRC

Description: NAK80 is a precipitation or age-hardened mold steel

with a uniform through hardness of approximately 40 HRc. It is

super clean, Vacuum-Arc Remelted steel with uniform grain

structure, uniform hardness, and excellent dimensional

stability.Unique Characteristics: Super clean, Vacuum-Arc Remelt

manufacturing process.40 HRc hardness.Age-hardened for uniformity

of hardness throughout, even in heavy sections.When welded, NAK

leaves no witness lines after re-aging.Uniform grain structure with

no pin holes, inclusions or hard spots.Machines up to 20% faster

than 30 HRc P20 mold steels.Never needs stress relieving, even

after heavy machining.Polishes to a superior No. 1 finish, even

over welded areas.Applications: Clear lens moldsExtremely critical

diamond finish applicationsMolds requiring special EDM

finishInformation provided by International Mold Steel.

Chemical composition of Tool and die steel HM NAK80

| Grade | C | Si | Mn | P | S | Mo | Ni | Cu | Al |

| HM NAK 80 | 0.10-0.20 | 0.20-0.40 | 1.20-1.80 | ≤0.015 | ≤0.003 | 0.20-0.40 | 2.50-3.50 | 0.80-1.20 | 0.80-1.20 |

Equivalent and related speciation for Tool and die steel HM NAK80

| Country | USA | German | Japan |

| Standard | ASTM A681 | DIN EN ISO 4957 | JIS G4404 |

| Grade | P21/P20+S | 1.2312 | NAK80 |

Tool and die steel HM NAK80 features

Special smelting methods ensures high purity,uniformly and compact structure ,and high mirror polishing performance .The pre-hardening of HM NAK80 is 38-42HRC . It has good processing performance ,hign mirror polishing performance and high demension accuracy and stability .The hardening can reach 40HRC .

Tool and die steel NAK80 property

Tool and die steel NAK80 Recommand heat treatment

| Hear temperature/℃ | Cooling way | solid solution Hardness (HRC) | Aging Temperature/℃ | Aging Hardness (HRC) | ||

| Preheating temperature | solid Solution temperature | |||||

| 500-600 | 850-910 | oil cooling or air cooling | 30-35 | 490-550 | 50-46 | |

Tool and die steel NAK80 applications

Technical service for Tool and die steel DVA/DVA-Nb

Vacuum heat treatment and surface treatment of mold .Oxynitriding ,carbonitriding ,carburizing and nitriding .

Other Tool and die steel we provided

| Catalogue | Grades | Size | |

| Diameter (mm) | Thickness*width (mm) | ||

| Plastic mold steel | S50C,S55C,S55C+Cr,HMSD2738,HMSD2738HH,P20, | Φ200-1200 | 160~1000×300~2000 |

| 4Cr13ESR,S136ESR,HMSD NAK80,1.2083,1.2316,1.2711,1.2714,1.2767 | Φ100-450 | 100~450×300~2000 | |

| Hot work die steel | HMSD 2344/PH13,HMSD DVN,HMSD DM,HMSD H13-MOD | Φ100-450 | 100~450×300~2000 |

| 1.2344/H13 ESR,1.2365/H10 ESR,1.2343/H11ESR,1.2367,3Cr2W8V/H21 ESR,5CrNiMo,H13F,SKD61 | Φ100-1000 | 100~600×300~2000 | |

| Cold work die steel | 1.2379/D2 ESR,HMSD DC53,SKD11,Cr12MoV ESR | Φ100-350 | 100~350×300~1000 |

About Guangda for die and tool steel

Guangda are professional die and tool steel manfuacturer and based on professional technologies,well-furnished equipmnets with rich experience. We provide high quality die steel materials: super large section pre-hardening plastic die , high polishing mirror die , high polishing mirror die , corrosion resistant mirror die , car lamp die steel, high heat strength hot die steel , high heat stability hot work die steel etc .

We are qualified by the classifications such as PED,DNV, BV, Rina, ISO, GL, ABS, LR .Act as the high-tech enterprises with high-quality special alloy materials as the core business belong to the "advanced iron and steel materials" industry under the strategic emerging industries supported by the state.

Products are widely used in automobille,machinery and electronics industry , home appliances ,defense and aerospace industry .Especially , the newly developed die-casting mold steel ,core bar for large diameter steel sleeves and big plastic mould block ,have filled in the technical blanks and reached the top quality in the world .At the same time ,we maintain leading role in advanced vacuum heat treatment technology and advanced surface technology with the support of the research Group .

Smelting

Forging

Heat treatment

Machining

Stock

NAK80

plastic mould steel

plastic mold steel

|