| Categories | CIP Washing System |

|---|---|

| Brand Name: | YGT |

| Model Number: | YGT-CIP |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1 set |

| Price: | negotiation |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5 set/month |

| Delivery Time: | 50 working days |

| Packaging Details: | shrink wrap |

| Name: | CIP washing system |

| Material: | SUS304 |

| Function: | to wash pipe, tank |

| Application: | dairy, juice drink, beverage etc |

| Company Info. |

| KUNSHAN YGT IMP.&EXP. CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Juice Drink Automatic Cip System / Cip Equipment To Wash Pipe , Tank

CIP system

Applications area: milk line, Beer, tea drink, beverage etc.

1 CIP Cleaning System

With the development of the video industry, CIP system has develop and improve. Initially cleaning on the tank, pipe and other equipment by the manual, time-consuming and ineffective. CIP system uses fluid circulation to clean tanks, piping and equipment, without disassembly to achieve the desired cleaning effect. CIP cleaning system to ensure a certain cleaning effect, improve product safety; save operating time, improve efficiency; save labor, protect the operation of security; save water, steam and other energy, reduce the amount of detergent; production equipment can be large-scale, High level; extend the service life of the production equipment.

2 CIP cleaning effect evaluation criteria as the food industry ideal CIP, cleaning effect must meet the standard:

2.1Odor: fresh, no different smell, for special processing of goods special settlement allows a slight smell but does not affect the final product safety and their own quality.

2.2 vision: clean the surface bright, no water, no film, no dirt or other.

2.3 effect: After CIP treatment, the production capacity of the equipment significantly changed, health-level indicators to meet the relevant requirements.

3 Applicable scope

Applicable to the entire fermentation engineering system cleaning, sterilization

4 Structure

4.1 All tanks are made of high quality 304 or 316 stainless steel materials, argon protection welding, polishing, outsourcing according to the requirements of processing, high-quality key valves.

4.2 Use automatic control technology and semi-automatic combination, according to the needs of customers to configure a reasonable

4.3 the cleaning tank has its own cleaning function.

5 Cleaning process

water- alkali--water--acid--water(design as per site)

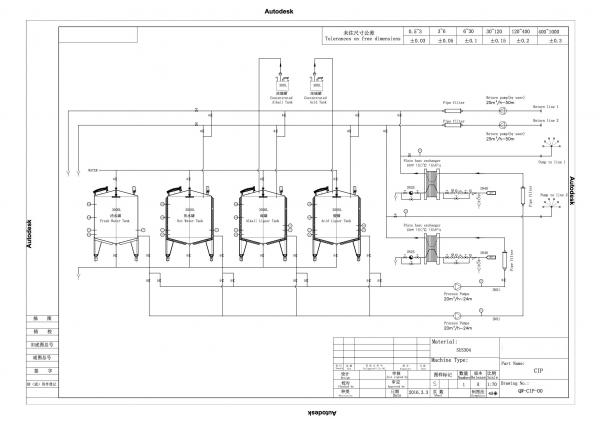

6 CIP station system

The CIP station consists of physical cleaning tank, chemical cleaning tank, pipe, pump, control system and accessory. Physical cleaning tank, chemical cleaning tank, pump, connected through the pipeline and to be cleaned equipment.Through the CIP control system to control on the cleaning fluid pressure, flow, temperature.

System configuration structure table

| Name | Specification | Quantity | Effect |

| Concentrated alkali tank | With insulation, superior hole, emptying device, liquid level display, temperature display, with a cleaner | 304 stainless steel | Store the concentrated base |

| Dilute the alkali tank | With insulation, superior hole, emptying device, liquid level display, temperature display, with a cleaner, inner coil heating, | 304 stainless steel | Alkaline cleaning |

| Concentrated cans | With insulation, superior hole, emptying device, liquid level display, temperature display, with a cleaner | Select 316 or 304 according to the nature of the acid used | Store concentrated acid |

| Dilute the alkali tank | With insulation, superior hole, emptying device, liquid level display, temperature display, with a cleaner, the coil heating, circulation back to the tube, according to process requirements to decide whether to add heating device | Select 316 or 304 according to the nature of the acid used 304 stainless steel | Acid cleaning |

| Hot water tank | With insulation, superior hole, emptying device, liquid level display, temperature display, with a cleaner, inner coil heating, | 304 stainless steel | Hot water rinse |

| Disinfectant tank | Single-layer tank, superior hole, emptying device, level display, temperature display, with a cleaner, inner coil heating, | 304 stainless steel | Disinfection cleaning |

| Sterile water tank | Single layer tank, superior hole, overflow device, liquid level display, with a cleaner | 304 stainless steel or 316L | Sterile water rinse |

| CIP pump | Low flow, high lift | 304 stainless steel | Cleaning, recycling |

| Heater | Tubular (in vitro) coil type (in vivo) sheet heat exchanger | 304 stainless steel | Heat the cleaning solution |

| Level display | Glass tube, differential pressure transmission | attaching | Display level |

| valve | Pneumatic valve or manual valve | 304 stainless steel | Cleaning control |

| Pipe filter | Oblique insertion | 304 stainless steel | Filter intercept |

| Control System | 1PLC control | 1attaching | 1Cleaning control |

The main equipments of CIP cleaning system are: hot alkali tank, cold alkali tank, acid tank, disinfection tank, recycling water tank, CIP transfer pump etc.

1. All tanks are adopted high-quality 304 stainless steel material, argon protection welding, inner and outer polishing processing, high quality valves and pipes, optimization technology link.

2. Adopt the automatic control technology, temperature, realized the automatic control of temperature, pressure, flow, liquid level etc, satisfy the need of automatic cleaning in every production connection.

3. Chose the advanced technology, the general cleaning process: hot water washing→ hot alkali water→ clean water→ acid water cleaning→ clean water→ ppm level hydrogen peroxide→ asepsis water; after finish of each link, recovery the washing and recycling using to reduce the environmental pollution.

2000L CIP Product classification: Transformation of fermentation engineering Applications area: Beer Bars, Hotels, Restaurants etc. Product features: 1. With insulation, superior hole...

|